CYTESTER™ (Cyanate Ester Monomer)

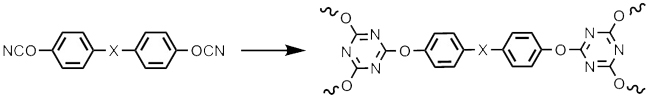

CYTESTER™ is a thermosetting resin containing –OCN groups. By repeating cyclotrimerization of three –OCN groups, cyanate esters form three-dimensional network polymers linked by triazine rings.

The polymers of CYTESTER™ possess excellent thermal and electrical properties. In addition, they can be modified by formulation with other thermosetting resins such as epoxies, maleimides and benzoxazines.

Structure and Curing Mechanism of CYTESTER™

- Properties of Cyanate Ester Monomers

- Low Melt Viscosity

- Good Solubility in Common Solvents

- Compatible with Other Resins

- Properties of Cured Resins

- High Tg

- Low Thermal Expansion

- Low Dk, Df

- Good Electrical Insulation

Main Applications

- Electronic Materials: Printed Wiring Boards for high frequency devices, Thermal Conductive Materials, etc.

- Structural Materials: FRPs, Adhesives, etc.

Properties of Homopolymers of CYTESTER™

| Unit | CYTESTER™ TA (Standard Grade) |

TA-100 (R&D Grade) |

TA-1500 (R&D Grade) |

P-201 (R&D Grade) |

Anhydride Epoxy Resin System*1 (Reference) |

|

|---|---|---|---|---|---|---|

| Feature | Standard | TA Prepolymers | Liquid at Room Temputure |

- | ||

| Melt Viscosity (40℃) |

mPa·s | Solid | Viscous Liquid | Solid | 28 | - |

| Melt Viscosity (80℃) |

13 | 660 | 71300 | 9 | - | |

| Tg*2 | ℃ | 325 | 330 | 325 | 296 | 150 |

| CTEα1*3 | ppm/℃ | 54 | 50 | 50 | 53 | 72 |

| Flexural Strength*4 |

MPa | 136 | 110 | 122 | 127 | 126 |

| Flexural Modulus*4 |

GPa | 2.8 | 2.9 | 2.9 | 2.6 | 2.8 |

- *1 DGEBF(curing egent Me-HHPA)

- *2 DMA

- *3 ASTM D696

- *4 ASTM D790

- Curing Conditions

- 150℃/3h+180℃/5h+250℃/3h (TA, TA-100, TA-1500, P-201)

100℃/1h+150℃/3h(Epoxy Resin)

All data are typical data and not guaranteed.

Inquiries Concerning Products

Green Energy & Chemicals Business Sector

High-performance Products Division

HP Material Department

TEL:+81-3-3283-4800 / FAX:+81-3-3214-0938