Environmental Management

Environmental Management System (ISO14001) (Non-consolidated)

All MGC plants have obtained Environmental Management System registration (ISO14001).

| ISO14001 Registration Date | |||

|---|---|---|---|

| Plant Registered | Registration Number | (1996 version) | (2015 version) |

| Niigata Plant | 1162-1998-AE-KOB-RvA | June 1998 | November 2017 |

| Mizushima Plant | JCQA-E-0145 | May 2000 | May 2018 |

| Yokkaichi Plant Naniwa Plant Saga Plant |

JQA-EM0502 | August 1998 (As the Yokkaichi Plant) |

August 2017 |

| Kashima Plant | JQA-EM0345 | February 1999 | January 2018 |

| Yamakita Plant | JQA-EM0859 | May 2000 | May 2018 |

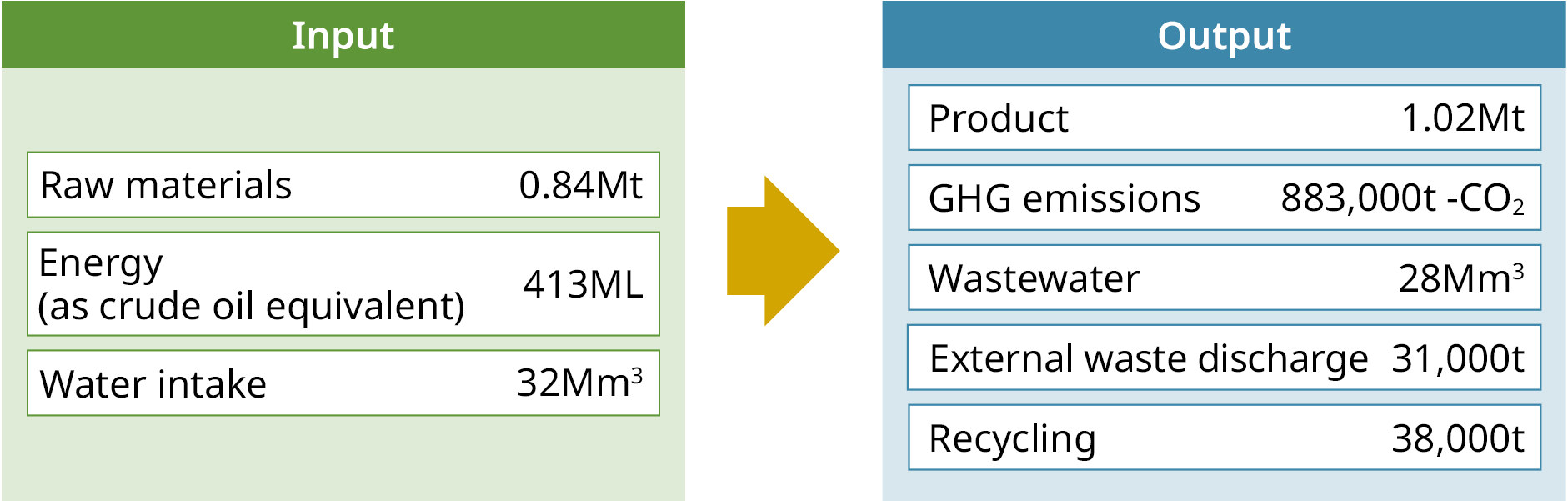

Production-related Input and Output (MGC non-consolidated and domestic MGC Group companies)

Primary production-related inputs and outputs for the non-consolidated MGC and domestic MGC Group in fiscal 2023 were as follows:

Environmental Preservation Investments (Non-consolidated)

MGC began undertaking environmental preservation investments in fiscal 2015, and it has continued these investments for ten years as of fiscal 2024.

These investments include investment items that, although they may be very effective in reducing environmental load, may be less likely to be adopted due to long payback periods or for other reasons, as well as investment items that lead to preservation of biodiversity, recruited through proposals from the various MGC sites. A secretariat consisting of the Environment, Safety and Quality Assurance Division and the Production Technology Division at corporate headquarters then select the items to implement and secure the required budget, before executing the investment.

The measures taken in the last ten years include the non-use of specified chlorofluorocarbons by replacing refrigeration equipment used in manufacturing, the reduction of power consumption by introducing inverter controlled rotating equipment, power saving by using thermal barrier coatings on buildings and thermal barrier films attached to windows and the improvement of work environments, the replacement of air-conditioning systems with energy-efficient systems, and the replacement of fluorescent lights and mercury lamps with LED lights to avoid the use of mercury and save energy.

With a cumulative investment of approx. 1.3 billion yen over the ten years, a reduction of a total of about 8,400 t-CO2e in greenhouse gas emissions was achieved.

MGC will continue to invest to reduce environmental impact.

Environmental Accounting (Non-consolidated)

Through environmental accounting in accordance with guidelines by the Ministry of the Environment, MGC has quantitatively calculated and released the investment amount and costs of environmental preservation required for the business activities of non-consolidated, as well as the real economic benefits obtained.

- Investment amount

The total amount of investment related to environmental preservation activities in fiscal 2024 was approximately 1.1 billion yen. The main investments were R&D investment relating to gas barrier materials and circular carbon methanol (CCM) production.

- Expenses

Total expenses related to environmental conservation activities in fiscal 2024 were approximately 11 billion yen. Of these, the highest expense was about 2.9 billion yen for R&D cost, accounting for around 27% of the total.

- Economic benefits

The reduction of expenses through energy saving measures and the income from the sale of unneeded items generated in our business activities were recorded as real economic benefit.

| Breakdown | Main areas of activity | FY2023 (millions of yen) |

FY2024 (millions of yen) |

||||

|---|---|---|---|---|---|---|---|

| Investment | Expenses | Investment | Expenses | ||||

| Onsite cost | Pollution prevention cost | Air pollution prevention | Exhaust gas treatment expenses, costs related to exhaust gas analysis | 16.1 | 553.7 | 12.5 | 961.1 |

| Water pollution prevention | Updating of aging facilities, updating of wastewater treatment facility | 108.9 | 1,293.4 | 55.7 | 1,533.5 | ||

| Soil, Noise | Costs related to ground subsidence | 0.6 | 46.5 | 0.0 | 3.2 | ||

| Global environmental preservation cost | Costs for upgrading to energy-efficient equipment and on-site power generation | 263.1 | 1,432.7 | 292.6 | 1,775.9 | ||

| Resource recycling cost | Liquid waste treatment costs and waste 3R promotion costs | 13.7 | 763.8 | 0.0 | 1,991.2 | ||

| Up or down stream cost | Environmental label maintenance costs | 14.3 | 5.9 | 0.0 | 1040.1 | ||

| Management activity cost | Environmental legal and regulatory compliance costs, and EMS operating costs | 0.5 | 398.5 | 3.3 | 698.5 | ||

| R&D cost | Research and development of energy-saving technologies and eco-friendly products | 1,187.1 | 28.4 | 808.2 | 2986.7 | ||

| Social contribution cost | Membership dues of nature conservation organizations | 0.0 | 16.0 | 0.0 | 43.9 | ||

| Environmental damage cost | Pollution impacts levy | 0.0 | 57.9 | 0.0 | 30.7 | ||

| Total | 1,604.3 | 4,596.8 | 1,172.3 | 11,064.7 | |||

| Title | Item | FY2023 (millions of yen) |

FY2024 (millions of yen) |

|---|---|---|---|

| Income | Profit on sale of valuable waste, etc. | 22.2 | 28.2 |

| Reduction of expenses | Effects due to energy saving | 225.2 | 867.0 |

- Compliance with the Ministry of the Environment's Environmental Accounting Guidelines 2005

- Period:From April 1, 2024 to March 31, 2025

- Scope:Non-consolidated

- Methods:Investments were apportioned according to the ratio of the approved or enforced amount of capital expenditure to environmental preservation.

Expenses were apportioned according to the ratio of expenses related to environmental preservation and include depreciation allowance.