Greenhouse Gas Emission Reduction

MGC considers risks associated with climate change to be an important business issue. It is moving forward with efforts to reduce emissions of greenhouse gas (GHG) and to reduce the negative impact of climate change on its business.

At the same time, new needs in society associated with climate change also represent a business opportunity. MGC recognizes that contributing to the achievement of a sustainable society through its products and technologies is an important issue.

Basic Approach to Climate Change Mitigation

- Formulate targets for reducing Scope 1 and 2*1 GHG emissions and steadily reduce them through planning, execution, monitoring and reassessment.

- Assess, manage, monitor and proactively disclose Scope 3*2 GHG emissions and take action to reduce them in collaboration with suppliers.

- Improve energy efficiency and raw materials' carbon cycle and promote energy transition toward realization of a zero-carbon society by 2050.

- Contribute to solving energy and climate change challenges through business operations by deploying innovative process technologies and factoring whole-lifecycle GHG emissions into design and development processes.

- Disclose information through climate change initiatives*3.

- *1 Scope 1 emissions are GHG emissions directly generated by MGC. Scope 2 emissions are indirect GHG emissions associated with use of energy (mainly electric power) purchased from external suppliers.

- *2 Scope 3 emissions are indirect GHG emissions generated in supply chains through organizational activities such as raw material sourcing, manufacturing, distribution, sales and waste disposal.

- *3 MGC proactively participates in various collaborative activities to mitigate climate change (climate change initiatives).

Greenhouse Gas Reduction Targets

MGC has quantitative set targets for reducing GHG emissions (Scope 1 & 2) and is taking action to achieve those targets.

| 2026 | 2030 | 2050 | |

|---|---|---|---|

| MGC Group | Reduce by 33% compared to 2013 | Reduce by 39% compared to 2013 | Achieve carbon neutrality |

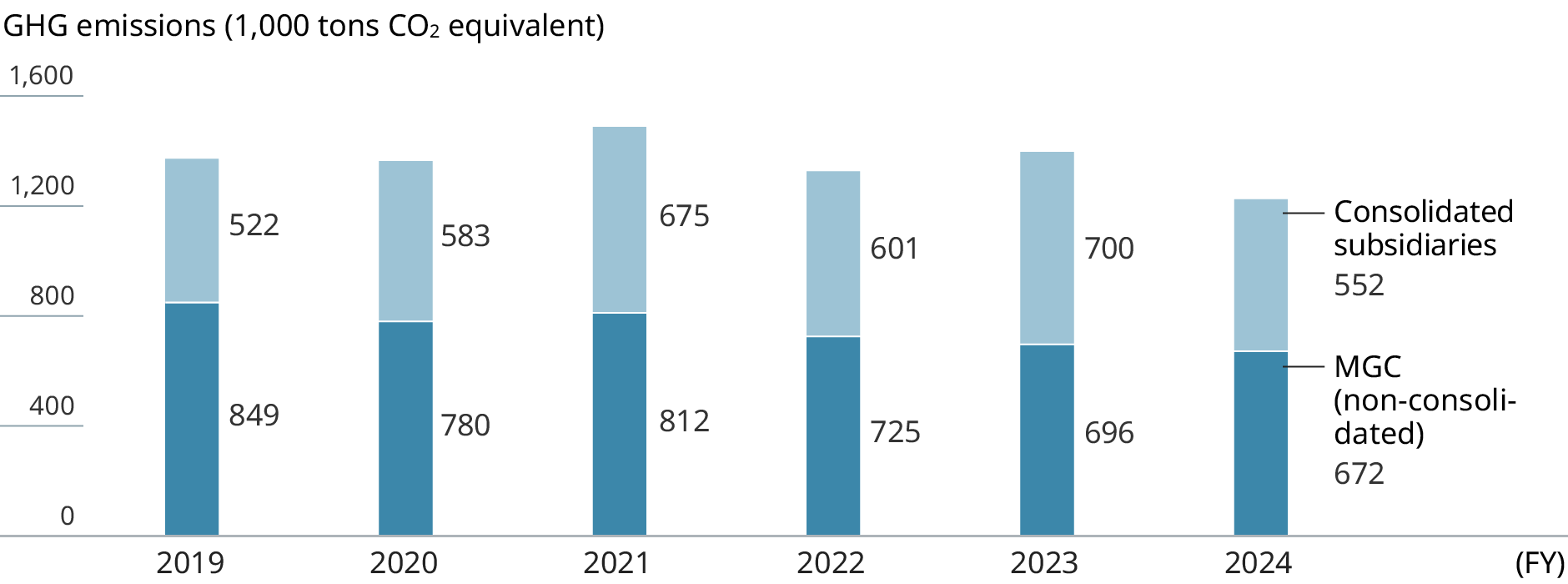

GHG Emissions

Results of energy consumption/GHG emissions in fiscal 2024

| Energy consumption | Scope 1 emissions | Scope 2 emissions | |

|---|---|---|---|

| (ML crude oil equivalent) | (1,000 tons CO2 equivalent) | (1,000 tons CO2 equivalent) | |

| MGC Group | 580 | 628 | 587 |

| MGC (non-consolidated) | 327 | 532 | 140 |

| Consolidated subsidiaries | 253 | 97 | 447 |

Scope 1 + 2 Emissions

Scope 3 Emissions (MGC Group)

Scope 3 emissions in fiscal 2024

| Category | Scope 3 Emissions (1,000 tons CO2 equivalent) |

||

|---|---|---|---|

| MGC (non-consolidated) | MGC Group | ||

| Cat.1 | Purchased goods and services | 3,358 | 6,003 |

| Cat.2 | Capital goods | 243 | 243 |

| Cat.3 | Fuel- and energy-related activities not included in Scope 1 or Scope 2 | 122 | 407 |

| Cat.4 | Upstream transportation and distribution | 418 | 548 |

| Cat.5 | Waste generated in operations | 12 | 35 |

| Cat.6 | Business travel | <1 | 1 |

| Cat.7 | Employee commuting | 1 | 1 |

| Cat.8 | Upstream leased assets | 3 | 4 |

| Cat.9 | Downstream transportation and distribution | 148 | 182 |

| Cat.10 | Processing of sold products | - | - |

| Cat.11 | Use of sold products | 406 | 460 |

| Cat.12 | End-of-life treatment of sold products | 2,517 | 2,727 |

| Cat.13 | Downstream leased assets | 11 | 20 |

| Cat.14 | Franchises | 0 | 0 |

| Cat.15 | Investments | - | - |

| Total | 7,240 | 10,631 | |

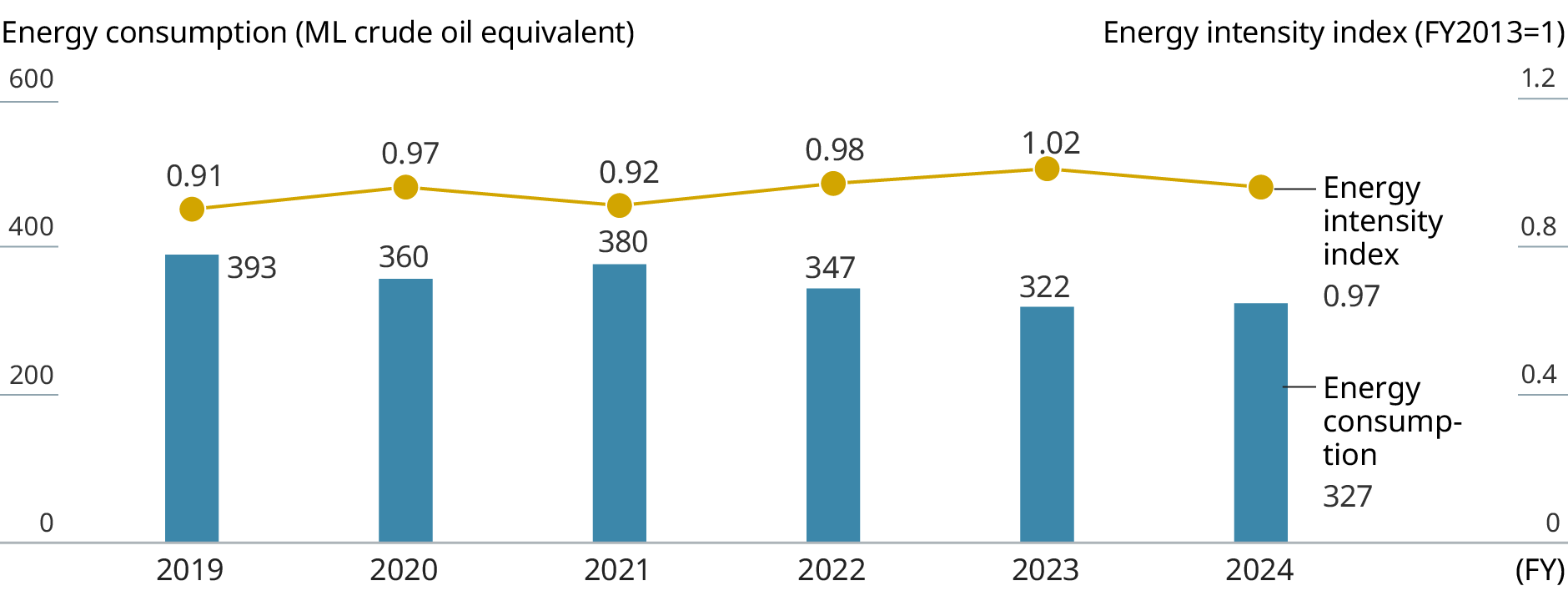

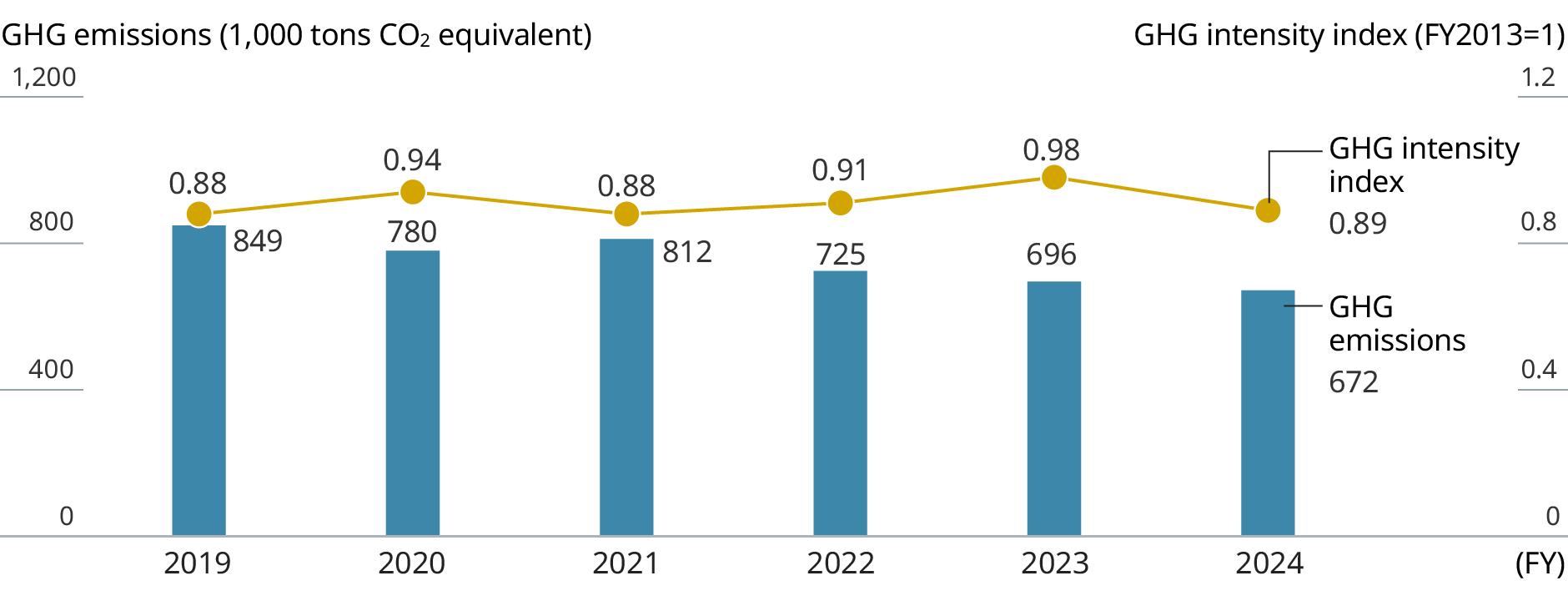

Energy-Saving and GHG Emission Reduction Initiatives (non-consolidated)

MGC is committed to energy conservation and GHG emission reduction. We will contribute to reducing environmental impact in terms of both resource conservation and GHG emissions from energy use by curtailing the use of fossil fuels. In fiscal 2024, we revised our co-generation systems and improved the controllability of distillation columns, among other initiatives. The GHG reduction effects from these measures are equivalent to 30,000 tons of CO2. In addition, we expanded the amount of renewable energy introduced as an energy source for production. The GHG reduction effects from the introduction of renewable energy are equivalent to 43,000 tons of CO2. In the future, we plan to enhance the recovery and utilization of byproduct fuels and implement energy conservation measures through reviewing manufacturing conditions, among other initiatives.

Energy consumption and energy intensity index of MGC (non-consolidated)

MGC non-consolidated GHG emissions and GHG intensity index

Third-Party Verification of Greenhouse Gas Emissions

A third-party organization has verified the GHG emission data reports disclosed by MGC to enhance reliability and transparency.

MGC GHG emissions (Scope1,2,3) have undergone third-party verification and have obtained a verification statement.

[Scope of Accounting and Verification]

Mitsubishi Gas Chemical Company, Inc., Scope1,2,3

[Targeted Period]

GHG emissions in FY2023 April 1, 2023 - March 31, 2024

[Accounting and Verification Standards]

GHG Protocol Corporate Accounting and Reporting Standard (reviced edition)

ISO14064-3:2019

[Verification Statement]

Verification Statement Scope1,2,3 emissions in FY2023

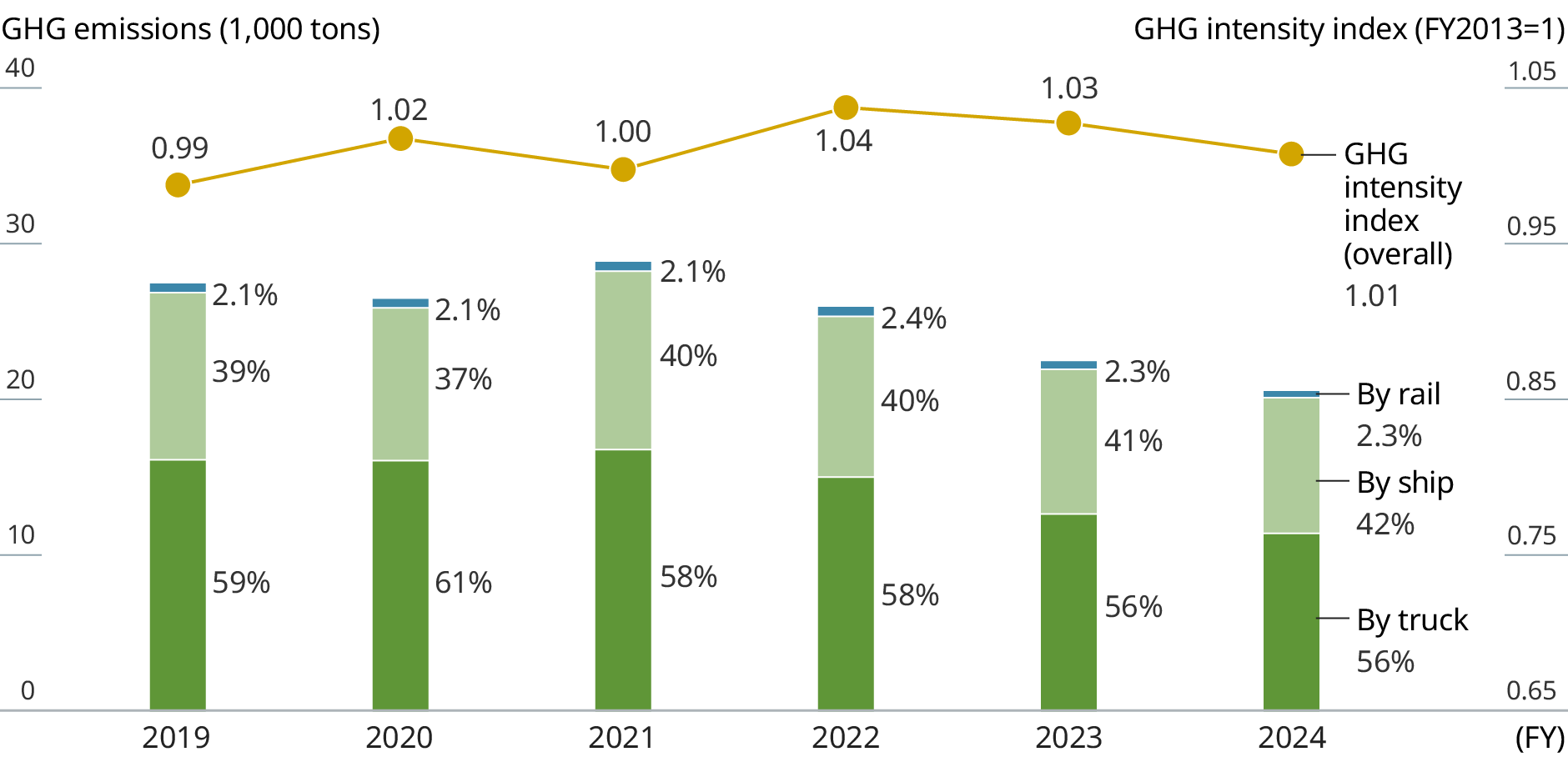

Initiatives in the Transportation Sector (non-consolidated)

In the Transportation Sector, MGC is implementing measures with a focus on modal shifts to more environmentally-friendly transportation methods to reduce energy consumption and GHG emissions. GHG intensity improved by 1.5% in fiscal 2021.

MGC transportation sector CO2 emissions

MGC Group products that contribute to reducing GHG emissions and that help lessen society's impact on the environment are featured on the Spotlight on Eco-Friendly Products page.

Spotlight on Eco-Friendly Products

The Mitsubishi Gas Chemical Group is aiming to achieve carbon neutrality by 2050, and is advancing its challenge to reduce CO2 emissions to net-zero using its unique technologies.

MGC’s Vision of Carbon-Neutral World Circa 2050

Various environmental data including GHG data is reported in the Sustainability Data Book.

In addition to this page, refer to the Sustainability Data Book.