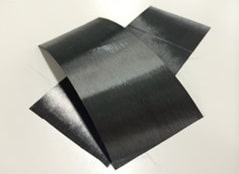

Thermoplastic Polyamide Uni-directional (UD) Prepreg, Reny™ Tape

Reny™ Tape is made of continuous fibers impregnated with high-performance polyamide resin.

It has high strength/stiffness, low moisture uptake and excellent stability of physical properties.

It can be used as a replacement for metal, or as a welding or reinforcement for metal, making products and parts lighter and thinner.

Features

- High strength, High stiffness

- Lower moisture absorption than PA6, PA66. and higher maintenance of properties

- Superior weldability with metal, which can make multi-materials

- Superior gas barrier property

Neat resin properties

| items | conditions | unit | PA-MXD6 | PA6 | PA66 |

|---|---|---|---|---|---|

| Density | 20℃ | 1.21 | 1.14 | 1.14 | |

| Moisture absorption | Immersion at 20℃ | % | 5.8 | 11.5 | 9.9 |

| 23℃65%RH | % | 3.1 | 6.5 | 5.7 | |

| Melting point | ℃ | 243 | 225 | 268 | |

| Glass Transition Temperature | DSC | ℃ | 75 | 48 | 50 |

Grade lineup

| Grades | Fiber | Fiber content | Specific gravity |

Width (mm) |

Thickness (mm) |

FAW (g/m2) |

Roll length (m) |

Roll weight (kg) |

|---|---|---|---|---|---|---|---|---|

| Reny Tape CF50 |

Carbon | 50wt% / 40vol% |

1.44 | 165+ | 0.15 | 110 | 500 | 18 |

| Reny Tape GF60 |

Glass | 60wt% / 42vol% |

1.76 | 165+ | 0.25 | 160 | 350 | 25 |

Mechanical properties

| items | Test method | Test conditions | unit | Reny Tape GF60% |

PA6 UD GF60% |

Reny Tape CF50% |

PA6 UD CF60% |

|---|---|---|---|---|---|---|---|

| Physical properties | |||||||

| Density | ISO 1183 | - | g/cm3 | 1.77 | 1.70 | 1.45 | 1.46 |

| Mechanical properties | |||||||

| Tensile modulus | DIN EN ISO 527-5 (or ASTM D 3039) |

23℃50%RH wet |

GPa | 33 | 30 | 87 | 90 |

| Tensile strength | MPa | 514 | 385 | 1400 | 1045 | ||

| Strain at break | % | 1.85 | 1.45 | ||||

| Tensile modulus | 60℃50%RH wet |

GPa | 31.4 | 78.1 | |||

| Tensile strength | MPa | 464 | 992 | ||||

| Strain at break | % | 1.57 | 1.22 | ||||

| Flexural modulus | DIN EN ISO 14125 | 23℃50%RH wet |

GPa | 34 | 33 | 85 | 89 |

| Flexural strength | MPa | 752 | 645 | 1330 | 705 | ||

| Flexural modulus | 60℃50%RH wet |

GPa | |||||

| Flexural strength | MPa | ||||||

| Compression modulus | ASTM D6641 |

23℃50%RH wet |

GPa | 42.4 | 84.7 | ||

| Compression strength | MPa | 498 | 982 | ||||

| Strain at break | % | 1.4 | 1.4 | ||||

| Compression modulus | 60℃50%RH wet |

GPa | 30.6 | 73.8 | |||

| Compression strength | MPa | 215 | 329 | ||||

| Strain at break | % | 0.8 | 0.5 | ||||

| Surfaceimpact (0/90/±45) Puncture Energy |

DIN EN ISO 6603-2 |

23℃50%RH wet |

J | 8.2 | 4.7 | ||

| Peal Force | kN | 3.9 | 3.2 | ||||

| Total Energy | J | 13.4 | 10.2 | ||||

| Surface impact (0/90) Puncture Energy |

J | 10.0 | 11.4 | 6.3 | 15.4 | ||

| Peal Force | kN | 2.9 | 3.2 | 2.7 | 2.6 | ||

| Total Energy | J | 11.8 | 15.8 | 8.3 | 17.5 | ||

| Thermal properties | |||||||

| DTUL | ISO 75-1, 75-2 |

1.80 MPa | ℃ | 238 | 240 | ||

| 0.45 MPa | 240 | ||||||

Application

It can be used for a wide range of applications, including automotive, aerospace, drones, sporting goods, building materials, and pressure vessels.

Inquiries Concerning Products

Green Energy & Chemicals Business Sector

Planning & Development Division

TEL:+81-3-3283-4763 / FAX:+81-3-3214-0938