MAXIVE™, Gas-barrier adhesive resin

Maxive™ is a solvent-based, two-component thermosetting epoxy resin with superior gas-barrier properties. It can simultaneously provide both adhesive and gas-barrier properties with dry laminate or by application. It also features superior barrier properties against various types of gases, as well as excellent transparency, chemical resistance, and aroma-retaining properties.

Advantages

- Excellent Gas Barrier Properties

- High Chemical Resistance

- Strong Adhesive with Variety of Films

- Improve Processability & Clarity

Basic Properties

| M-100 | Component | C-93 |

|---|---|---|

| Polyepoxy Resin | Material | Polyamine Resin |

| Colorless Clear Liquid | Appearance | Colorless Clear Liquid |

| 100% | NVM | 65% |

| 2000mPa・s | Viscosity (25℃) | 1300mPa・s |

Barrier Properties

| Gas | Unit | Condition | MAXIVE™ | EVOH |

|---|---|---|---|---|

| Oxygen | cc・mm/m2/day/atm | 23℃/60%RH | 0.03 | 0.01 |

| 23℃/80%RH | 0.04 | 0.09 | ||

| 23℃/90%RH | 0.06 | 1 | ||

| Water Vaper | g・mm/m2/day | 40℃/90%RH | 0.7 | 0.7 |

| Fuel | g・mm/m2/day | 60℃ | 0.05 | 0.18 |

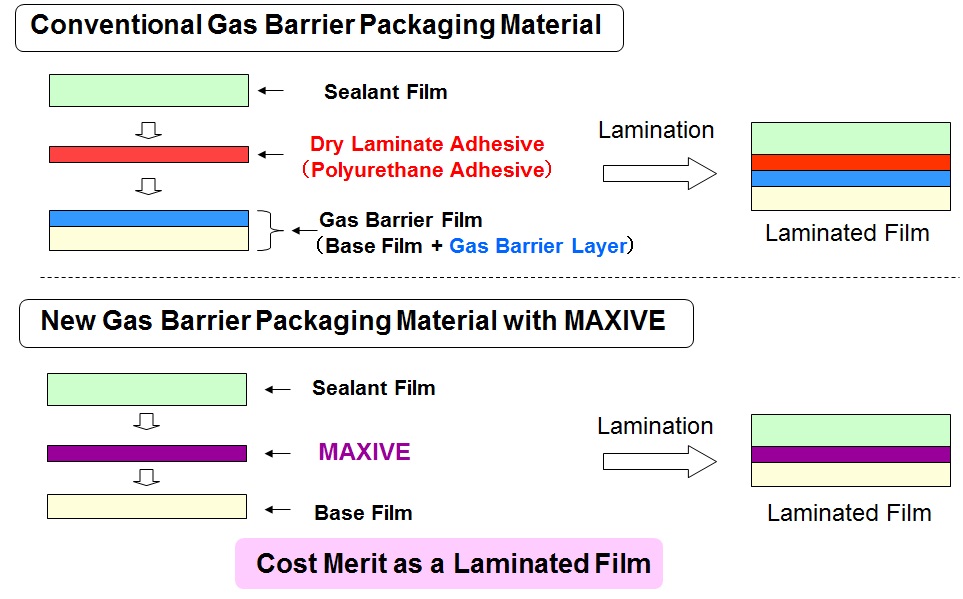

Adhesive and Barrier Film Application

|

|

|---|

Typical Use Prescription

| Formulation | |

|---|---|

| M100 | 5 |

| C-93 | 16 |

| Pigments | 1 |

| PGM | 20 |

| Ethanol | 2 |

| Ethyl acetate | 3 |

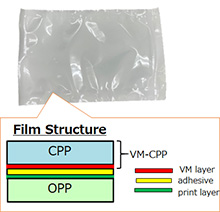

Combination of MAXIVE™ and VM-films

| Item | MAXIVE™ | Urethane |

|---|---|---|

| OTR (cc/m2・day・atm) |

0.01 | 14.7 |

| WVTR (g/m2・day) |

0.1 | 0.1 |

| Peel Strength (g/15mm) |

280 | 300 |

*Condition OTR: 23℃/60%RH, WVTR: 40℃/90%RH

*The values listed are not guaranteed ones.

- Achieve mono-material packages having high gas barrier properties.

- De-aluminum foil and easy recycling leading to environmental load reduction.

- Improve more than 1,000 times in oxygen barrier property.

*VM: Vacuum Metallizing

Product Brochure

Inquiries Concerning Products

Green Energy & Chemicals Business Sector

Planning & Development Division

TEL:+81-3-3283-4763 / FAX:+81-3-3214-0938