Energy and resource saving

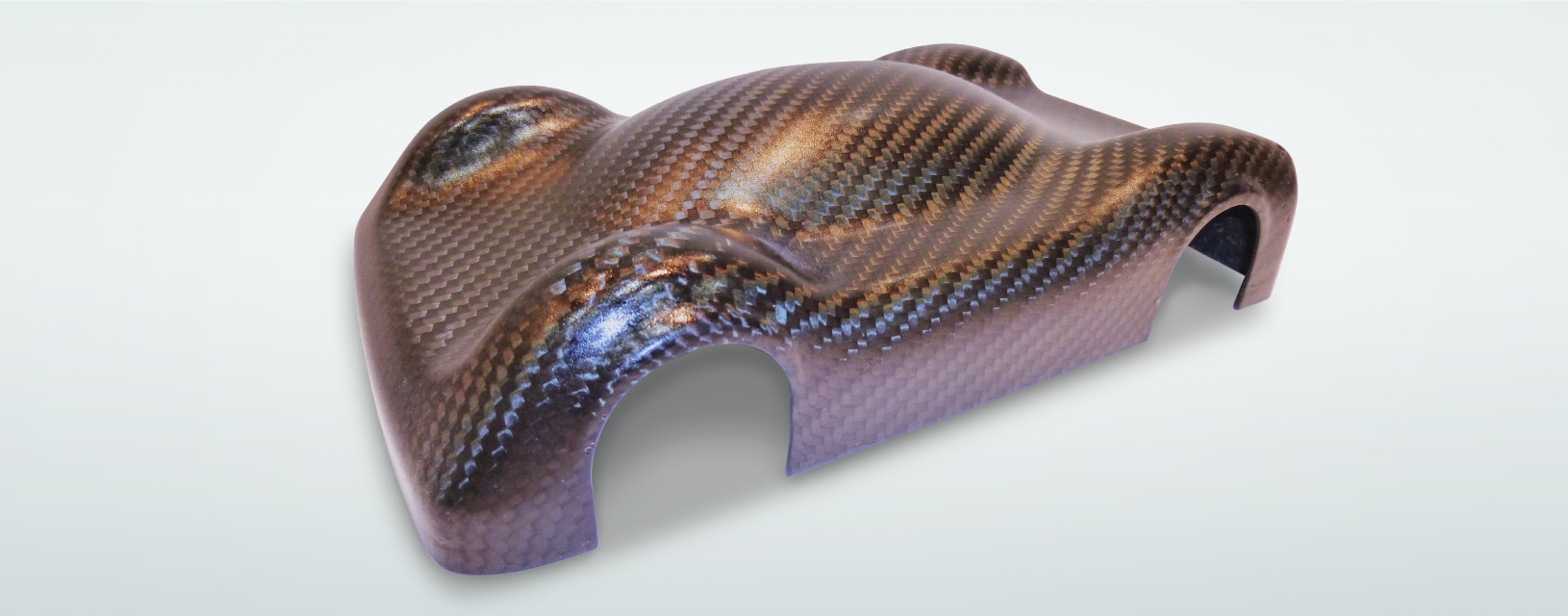

CBZ thermosetting resin

Resin exclusively for use in carbon fiber reinforced plastic

Contributes to energy and resource savings during processing and use

Benefits for the environment

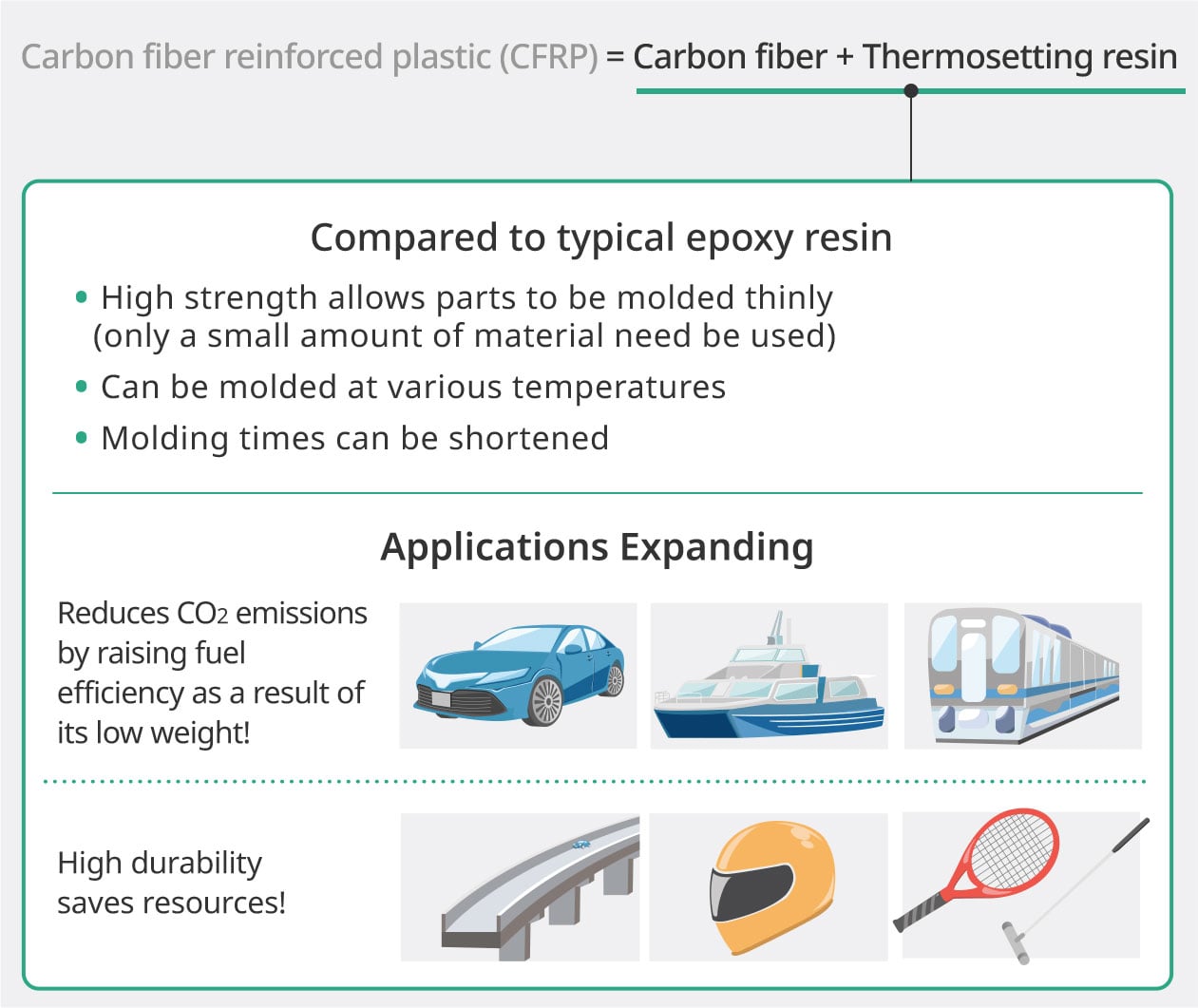

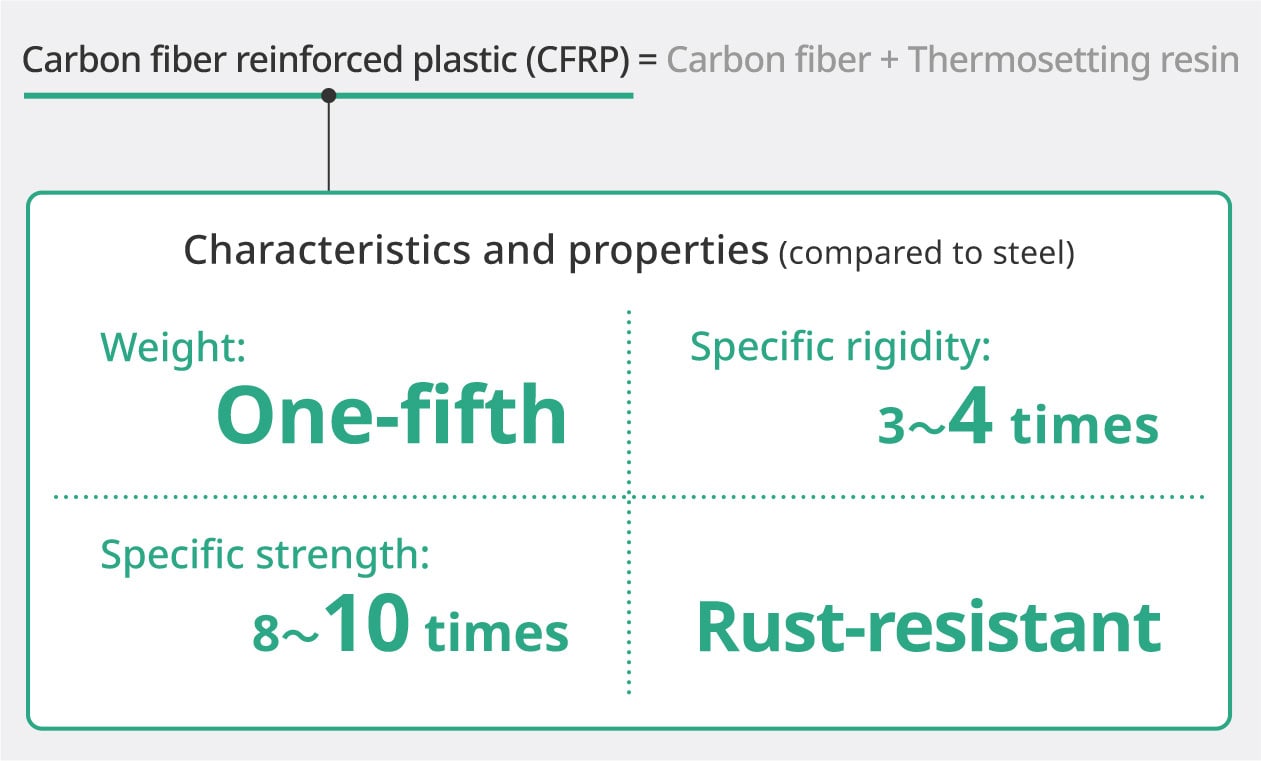

Carbon fiber reinforced plastic (CFRP) is attracting attention for its energy and resource saving effects during use because of its light weight and sturdiness. Thermosetting resin is essential for molding CFRP.

CBZ can be molded at various temperatures and curing times are short. As a result, energy consumption is reduced during molding, and the resin itself is high strength, which means it can be molded thinly, contributing to resource saving.

Composition of CBZ and characteristics / properties of CFRP

characteristics / properties of CBZ

- * Products of Japan U-PiCA, a member of the MGC Group.

Chemical blowing agents

Chemical products that foam resin and rubber

The power of bubbles enhances material functionality and saves energy and resources

Benefits for the environment

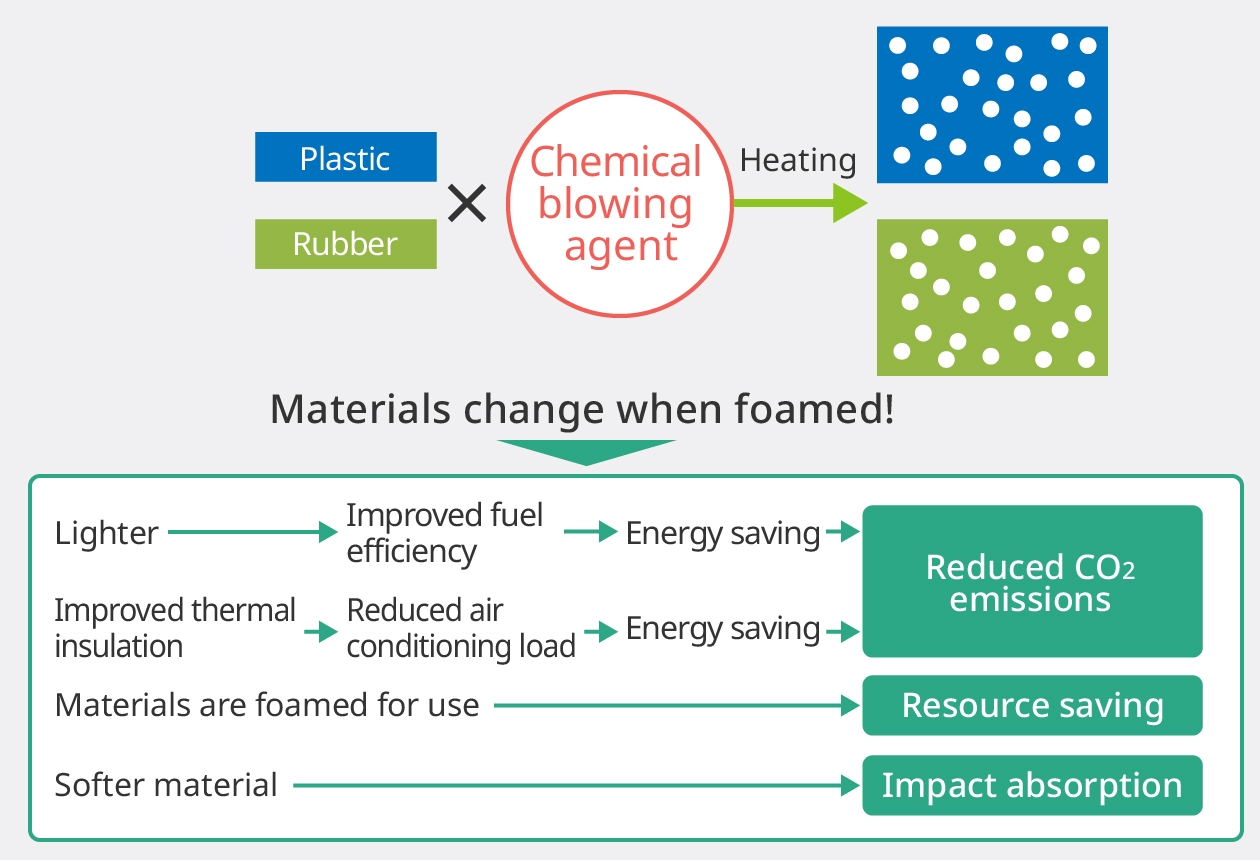

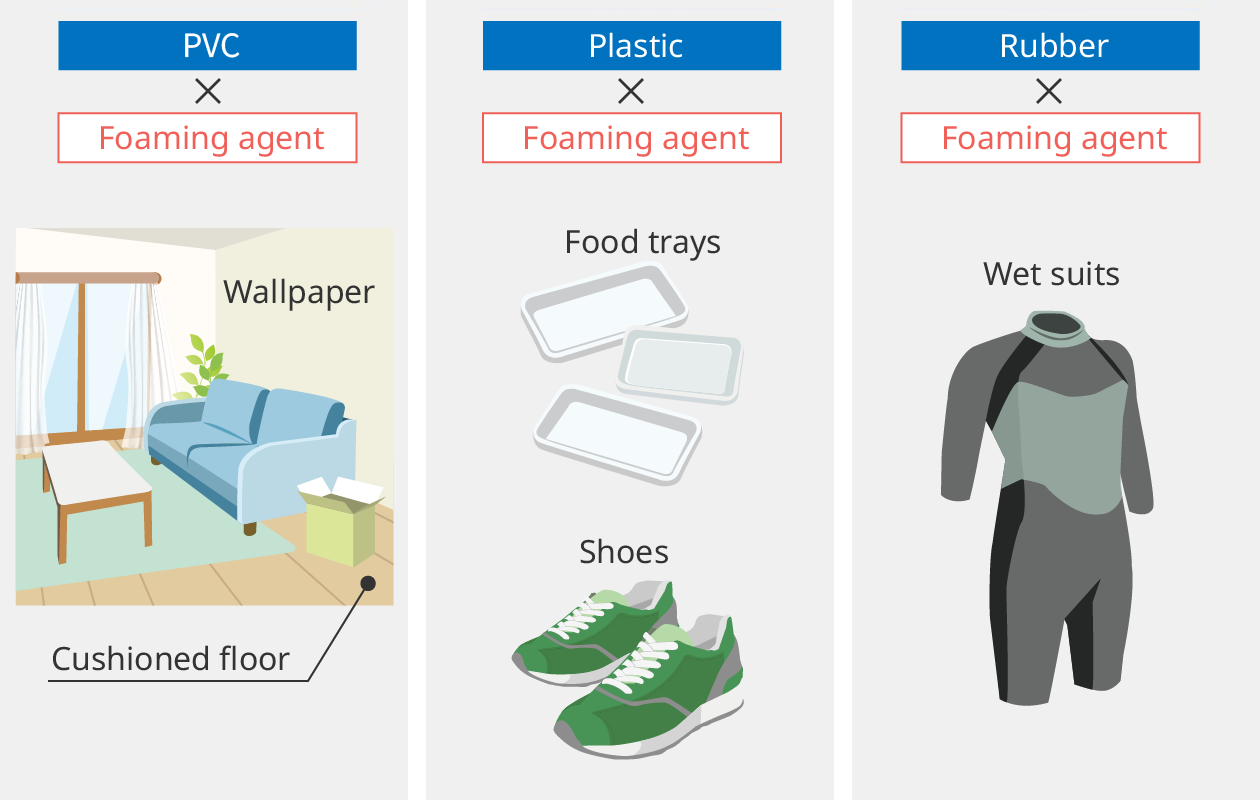

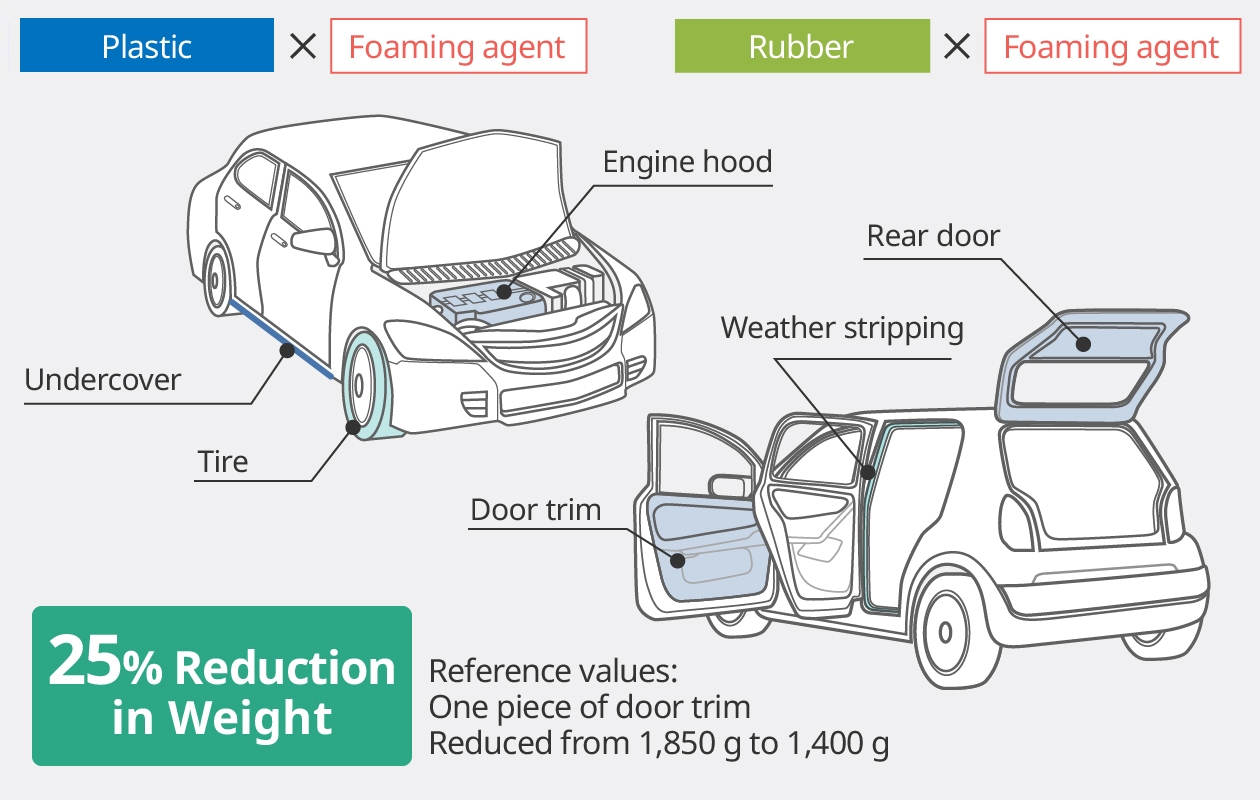

It is possible to produce materials with excellent properties including light weight, thermal insulation, noise absorption, and vibration absorption by chemically foaming rubber and plastic.

These types of foamed materials are used in many everyday products including automobile components, tires, and building materials such as wallpaper. They contribute to energy and resource saving.

Properties of foamed plastic and foamed rubber

Applications in the home

Applications in automobiles

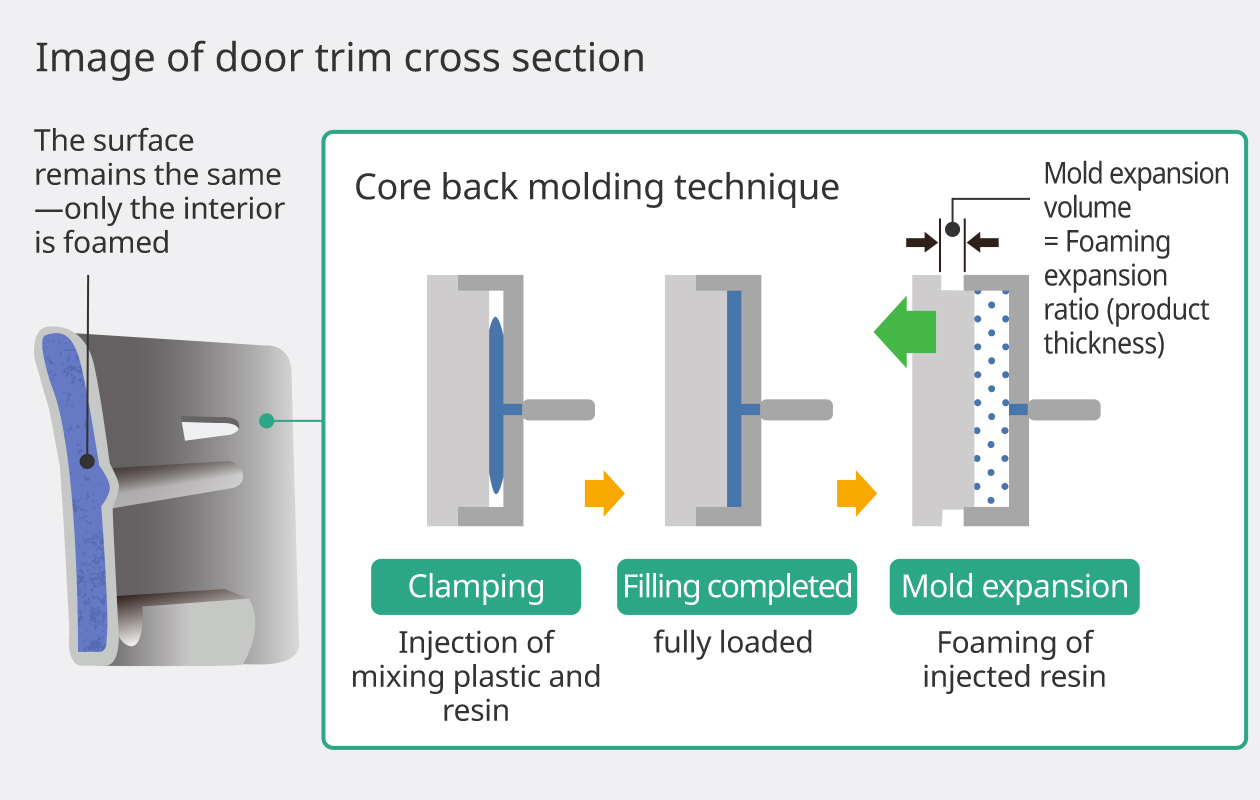

Core back molding technique

Foamed plastic and rubber have many other applications including sound absorption and vibration control by components that are not seen in the interiors of the ceiling, floor, and doors.

- * Products of Eiwa Chemical Ind. Co., Ltd., a member of the MGC Group.

Ageless™ oxygen absorbers

Preserves the freshness and taste of food for longer periods

Helping reduce the amount of wasted food

Benefits for the environment

Ageless™ can keep food tasting delicious and fresh for relatively long times, which leads to less food being thrown away due to mold, discoloration, or loss of flavor. That also helps reduce the amount of times food needs to be produced and delivered, which ultimately means less CO2 emissions.

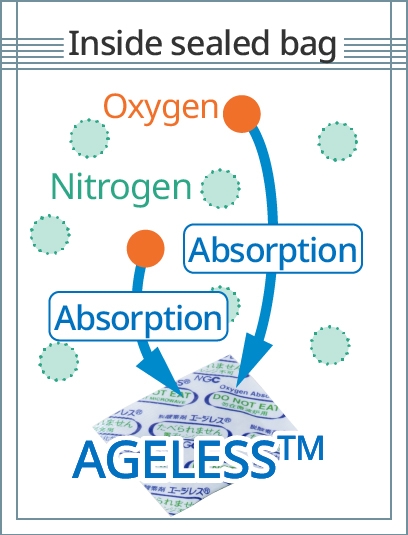

How Ageless™ works

Ageless™ is mainly comprised of specially processed iron powder. One property of iron is that it bonds with oxygen as it rusts. That allows Ageless™ to effectively absorb the oxygen in an airtight package, thereby preventing adverse effects from oxygen and oxidation on the items in the package.

The effectiveness of Ageless™ in preserving food

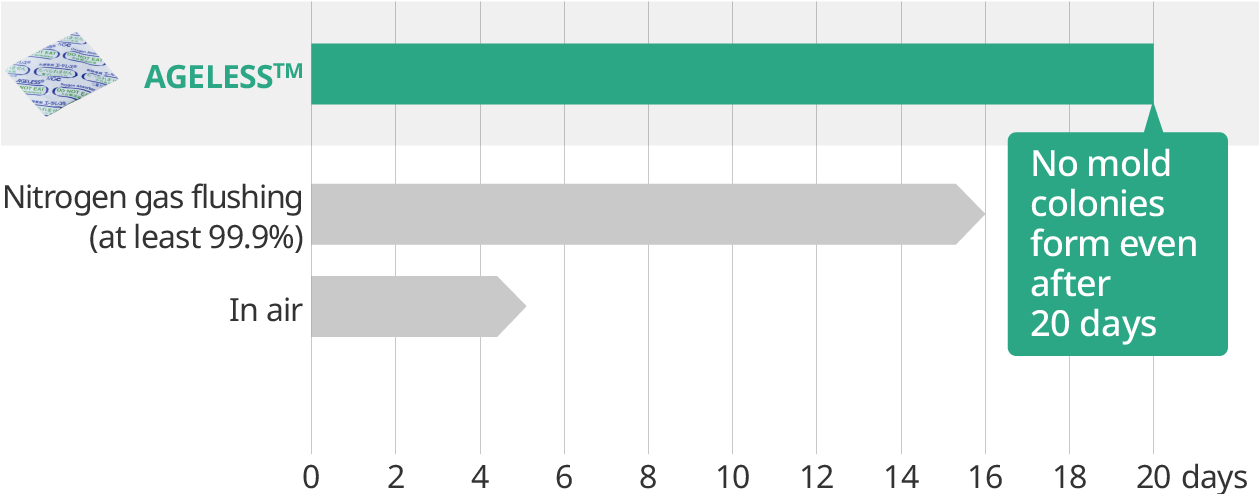

Testing the ability of Ageless™ to prevent mold

Under experimental conditions, the colonization of blue mold was observed on castella sponge cake either in packaging containing an Ageless™ sachet, in nitrogen flushed packaging, or exposed to the air.

DESLIME

Cleaning agent for air conditioning equipment

Cleans air conditioning equipment and saves energy

Benefits for the environment

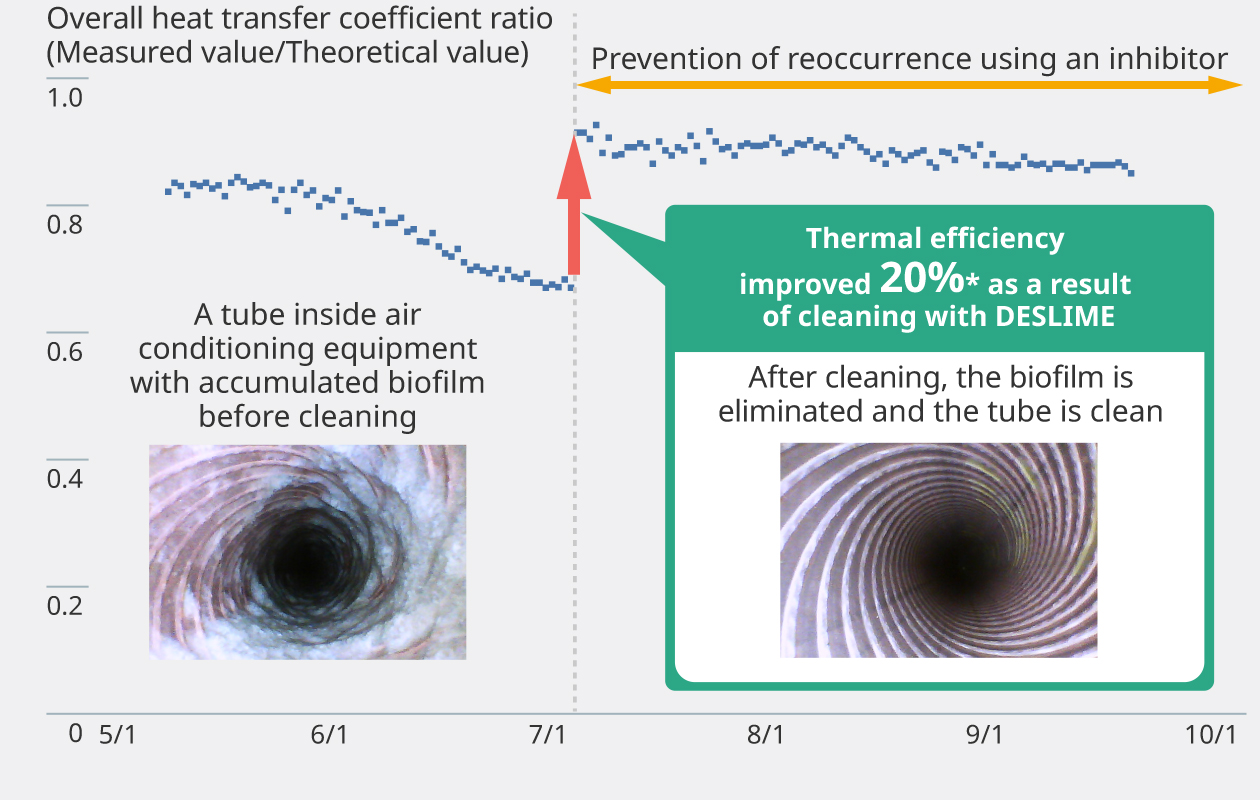

When a biofilm firms inside air conditioning equipment, thermal efficiency declines and excess energy is consumed. DESLIME contributes to energy saving by easily removing this biofilm.

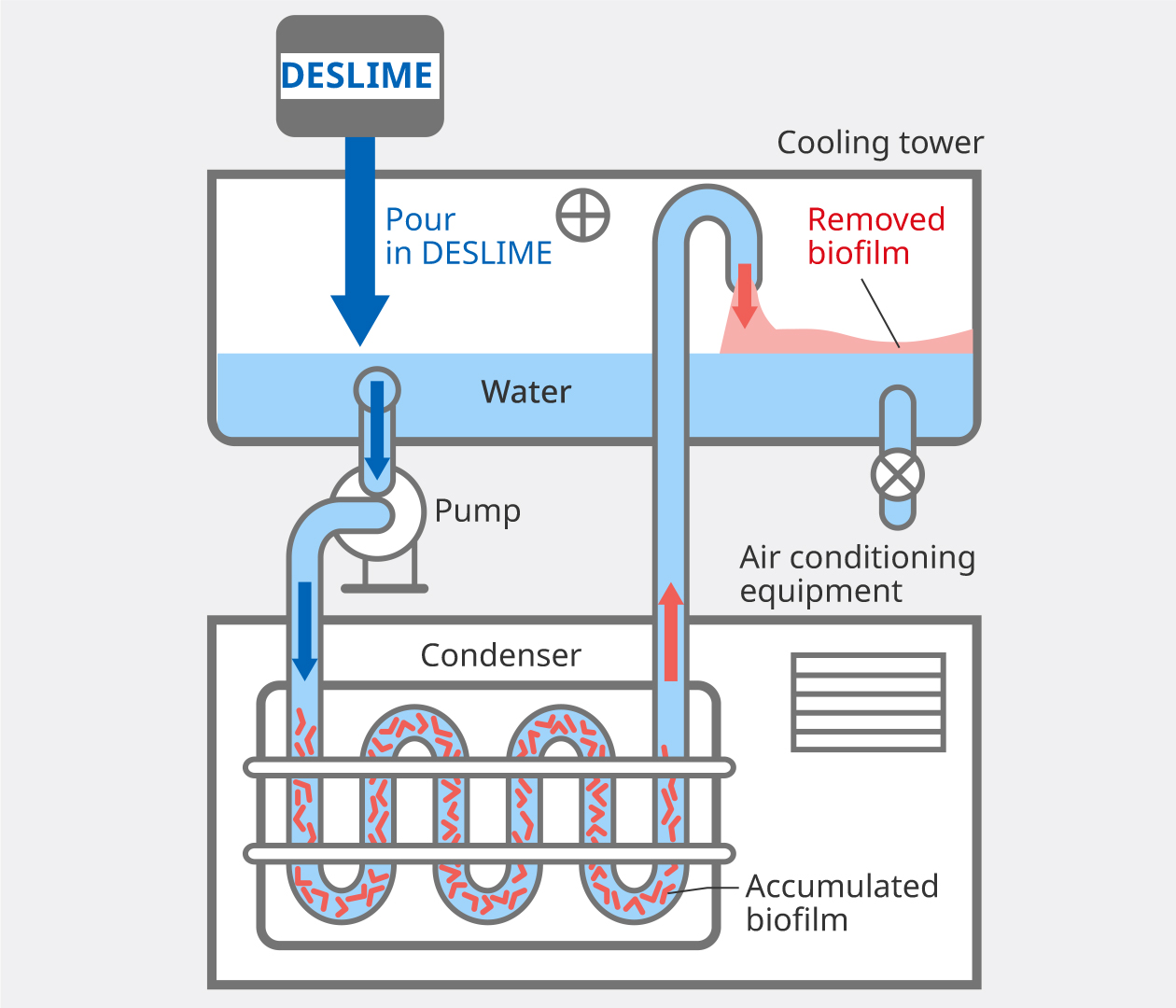

- Simple cleaning operation

Place DESLIME equal to 5% (standard use concentration) of the water capacity in the water reservoir.

Use the pump to circulate the water for one to two hours. - Environmentally friendly

After cleaning, DESLIME breaks down to non-toxic water and oxygen.

- Cleaning fluid has a neutral pH

DESLIME has almost no impact on equipment materials.

- Excellent dispersion and separation force

DESLIME is a peroxide-based cleaning agent that penetrates and removes accumulated biofilm in air conditioning equipment.

Explanatory diagram for the total system cleaning method

Example of cleaning using DESLIME

- *Results will vary depending on the status of biofilm accumulation.

Powerful disinfecting ability

DESLIME is also ideal for removing Legionella spp. and general bacteria.

DESLIME is registered with the Japanese Association of Air Conditioning Water Treatment Chemicals for Legionella.

Cleaning with DESLIME and general bactericide (example of measurement using a bio-checker)

MX-Nylon

Containers and packaging materials that boast excellent barrier properties and chemical resistance

Reducing the burden on the environment by extending the shelf life of foods and beverages and using thinner and lighter containers

Benefits for the environment

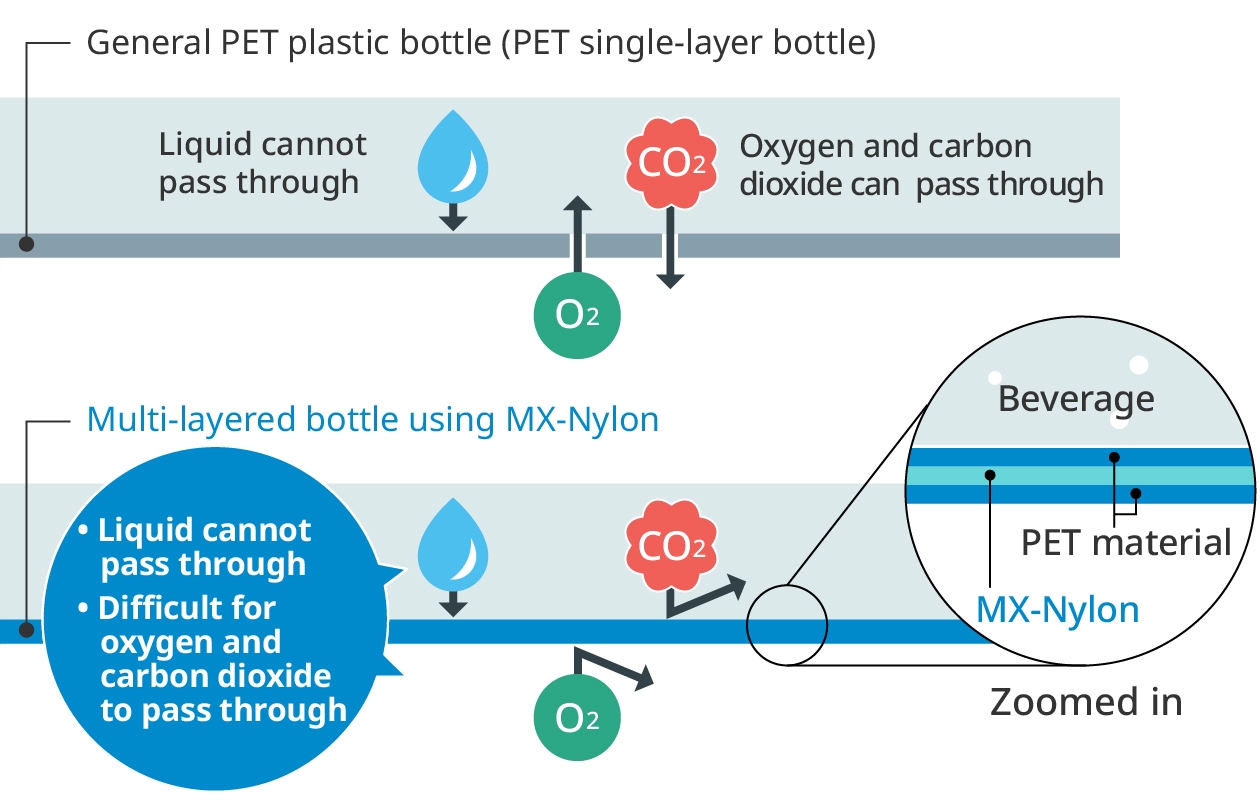

By making containers thinner and lighter while maintaining their excellent barrier properties against oxygen and carbon dioxide gas, MGC helps to solve environmental problems by preserving foods and beverages for long periods, reducing the amount of plastic usage, and reducing CO2 emissions produced in distribution operations.

- *Thinner: reducing the thickness of containers, etc.

Mechanism of barrier property of MX-Nylon (for plastic beverage bottle)

- *PET: polyethylene terephthalate

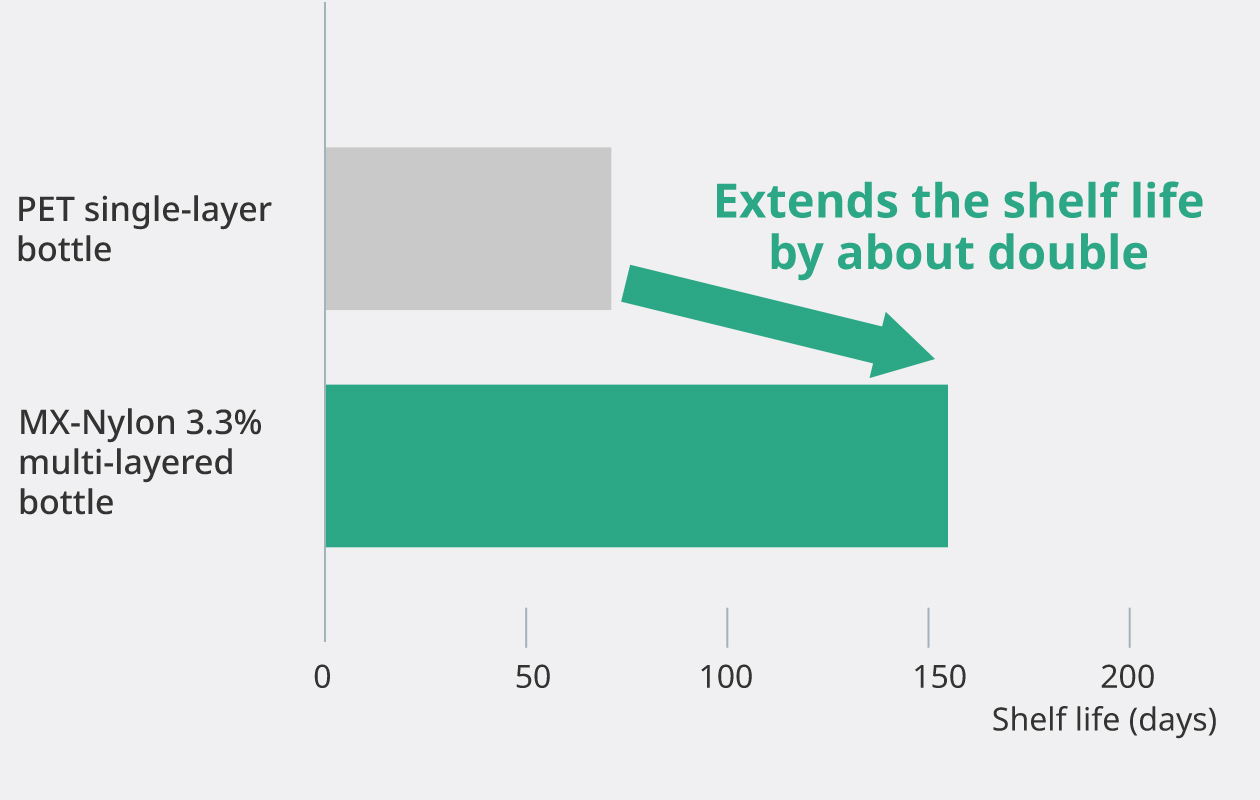

Effect of MX-Nylon’s barrier performance

The excellent gas barrier properties extend the shelf life by about double (for a 350ml PET plastic bottle of a carbonated beverage).

Period for maintaining the carbon dioxide gas (shelf life): the period until 20% of the initial CO2 GV is lost.

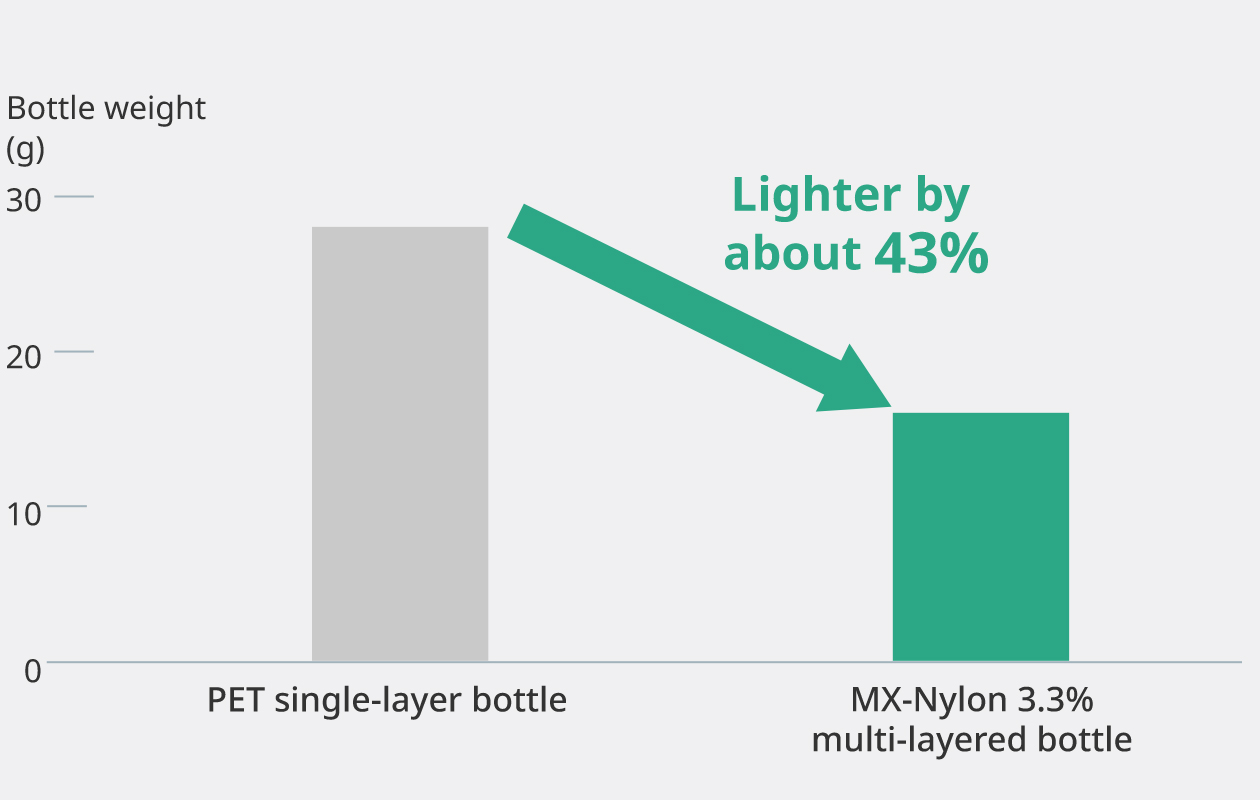

Effect of MX-Nylon’s lightweight design

Lighter containers (for a 350ml PET plastic bottle of a carbonated beverage)

Weight of bottles with the same shelf life

A wide range of applications

MX-Nylon is used for various food containers and packaging including PET plastic bottles, films, pouches, cups, and trays. Taking advantage of its excellent chemical resistance, MX-Nylon is also used for chemical and fragrance bottles as well as bleach (chlorine bleach) and ink containers, and can preserve contents for long periods and prevent the leaking of odors.

Development to also achieve carbon neutrality

MX-Nylon, to be produced at MGC’s Niigata Plant, has acquired ISCC PLUS certification, an international certification system for sustainable products.

With this certification, MGC will begin manufacturing and selling ISCC PLUS-certified MX-Nylon, which is manufactured from sustainable raw materials as per the mass balance approach .

In order to meet the carbon neutral goal, by conserving energy in its manufacturing process and actively using plant-derived raw materials, MGC is working to achieve net-zero CO2 emissions when manufacturing.