Environmental (atmosphere, water quality, soil) protection

Direct methanol fuel cells

Enabling quiet and clean power generation

Supplies power without emitting any NOx, SOx, particulate matter or other atmospheric pollutants

Benefits for the environment

Direct methanol fuel cells (DMFCs) produce power through a chemical reaction, so they operate quietly and emit no atmospheric pollutants. They can also continuously supply electricity for several consecutive days.

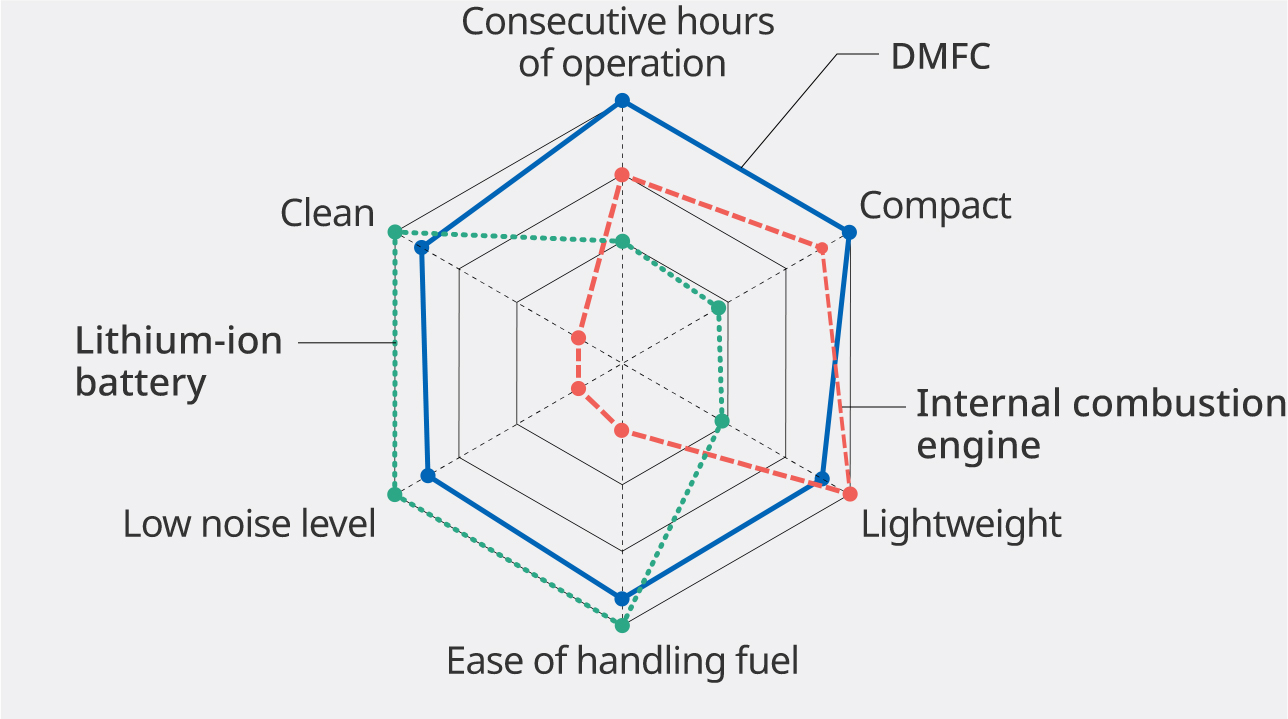

Comparing the performance of DMFCs with other emergency power supplies

DMFCs are clean sources of energy that operate at low noise levels, and meet high-performance standards for applications that require relatively low output of electricity to be supplied continuously for long periods of time. Since the cells are also compact, they can be installed in small spaces for use in times of emergency.

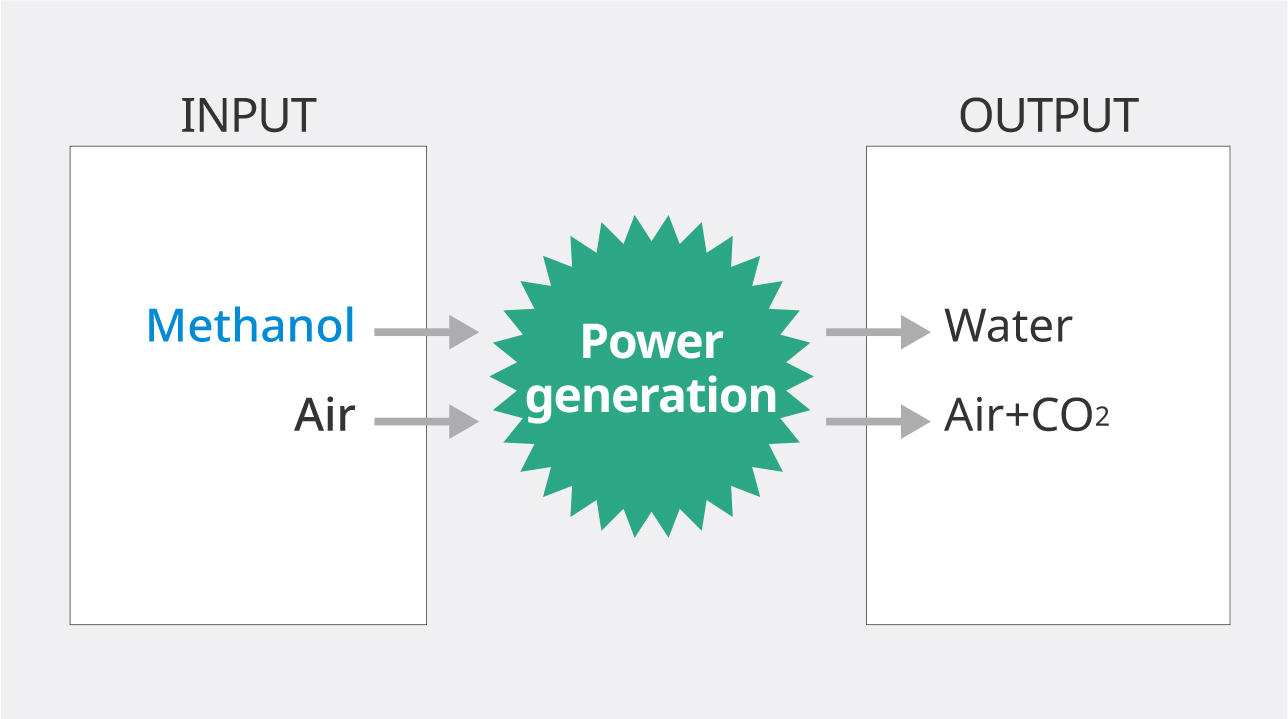

How DMFCs work

DMFCs generate electricity by producing a chemical reaction using methanol and air. DMFCs can continuously supply electricity as long as they are filled with methanol.

Dimethyl ether

A clean fuel derived from methanol

Emits comparatively low amounts of NOx and no SOx and PM during combustion

Benefits for the environment

MGC produces dimethyl ether as well as methanol from natural gas produced as a by-product of oil drilling, thereby making effective use of resources from an environmental perspective. Dimethyl ether is also being promoted as a clean fuel because it emits no sulfur oxide (SOx) and particulate matter (PM), which are emitted when burning diesel oil or kerosene.

Aerosol spray cans

As an alternative to chlorofluorocarbons (CFCs), MGC's dimethyl ether is used in aerosol spray cans as a propellant.

Plastic greenhouses

MGC is aiming to commercialize dimethyl ether as a greenhouse boiler fuel that facilitates cultivation since it emits CO2 needed for the growth of plants and Produces while also providing heating.

Trucks

MGC's dimethyl ether can be used as a clean diesel fuel for trucks.

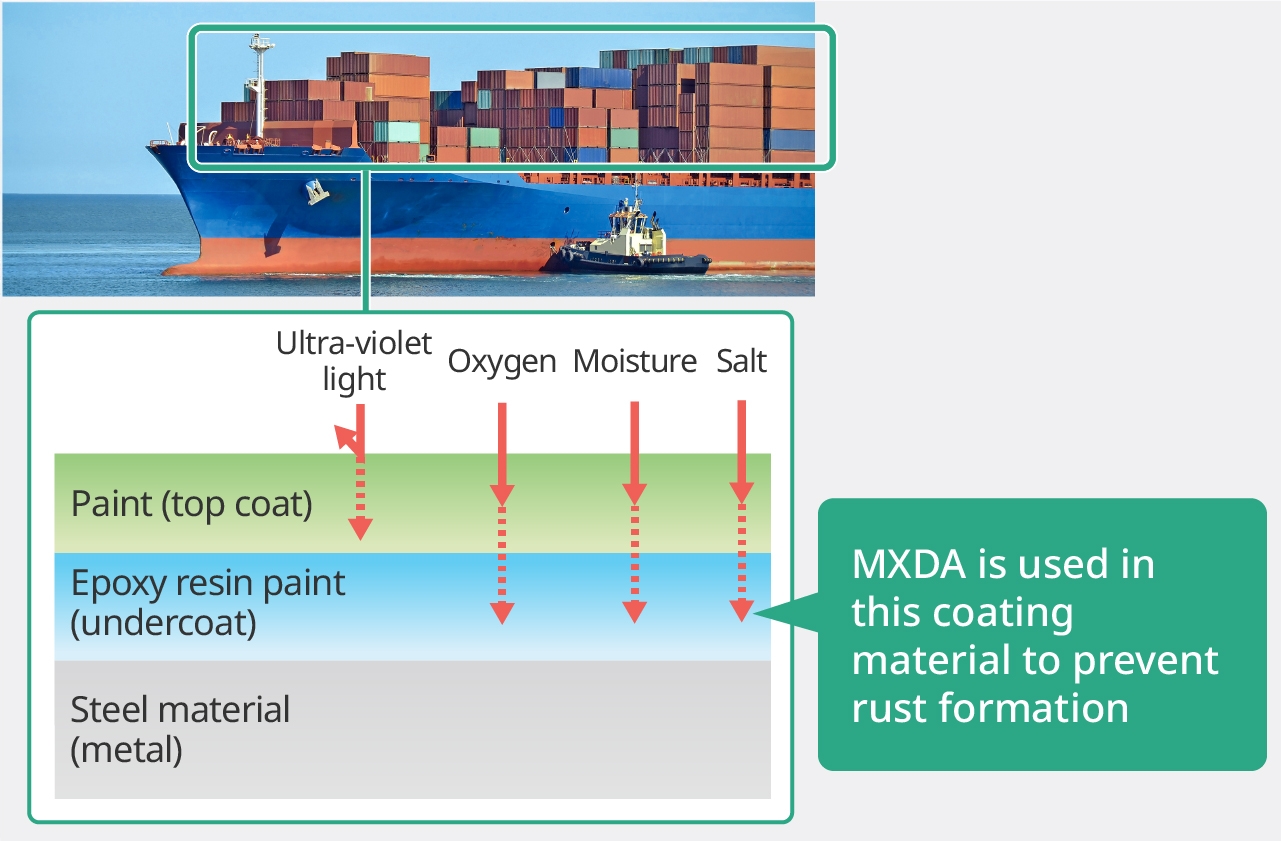

Meta-xylenediamine

A highly weather-proof epoxy coating

Reduces organic solvents to the greatest extent possible!

Benefits for the environment

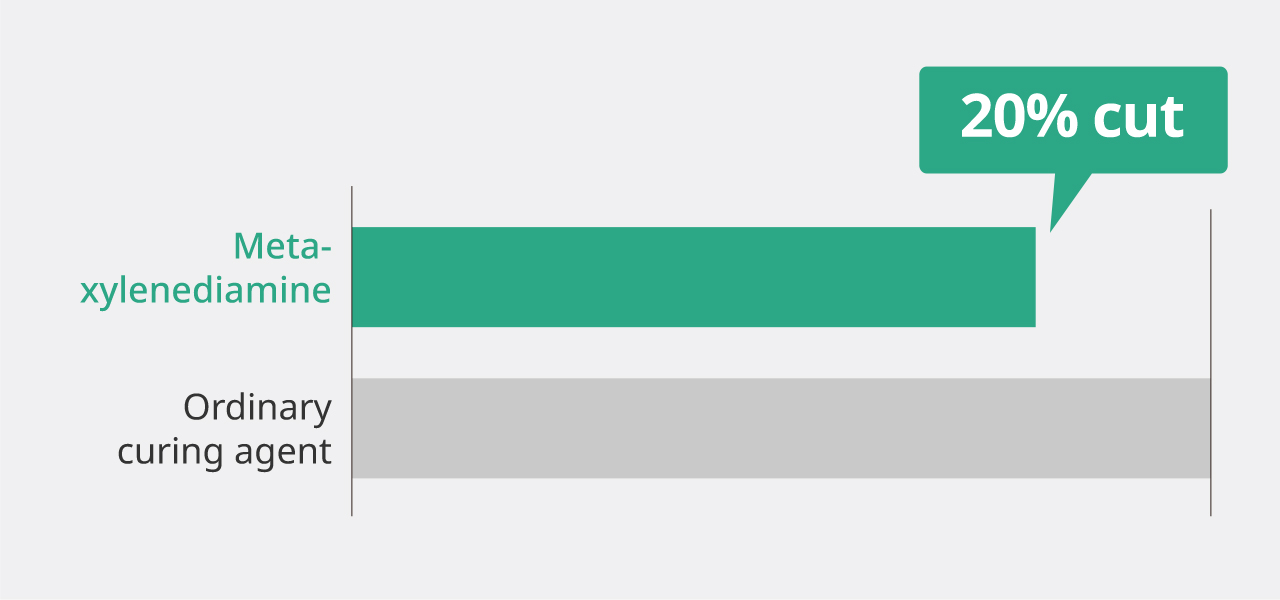

MGC's meta-xylenediamine (MXDA) epoxy coating is comparatively friendlier to human health and the environment than conventional products because it is water-based and contains no organic solvents, which are a cause atmospheric pollution. Compared with ordinary curing agents, about 20% less volume of MXDA is needed to get the same hardening performance, which ultimately contributes to conserving oil resources.

Comparing MXDA and an ordinary curing agent by the amount of needed for the same performance

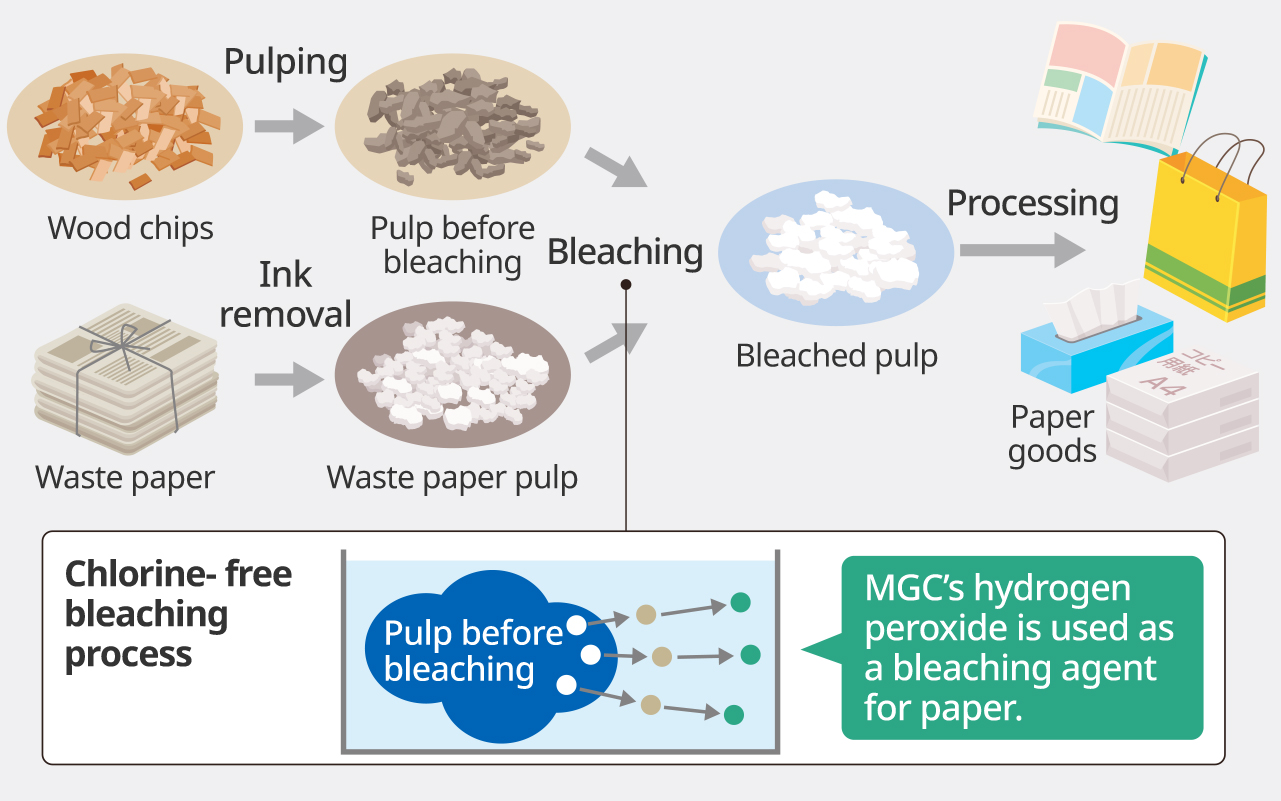

Hydrogen peroxide

An environmentally friendly pulp and paper bleaching agent

Hydrogen peroxide is used as a bleaching agent that does not harm marine ecosystems because it decomposes into water and oxygen

Benefits for the environment

Hydrogen peroxide is a chemical compound that has been used as a bleaching agent and an oxidizer for many years. It produces no harmful by-products since it decomposes into water and oxygen. Consequently, hydrogen peroxide is in demand for various applications as an environmentally friendly chemical.

Using hydrogen peroxide instead of chlorine to bleach paper products

After successfully manufacturing hydrogen peroxide for the first time in Japan in 1933, MGC went on to become one of the world's leading producers of this substance.

The first hydrogen peroxide manufactured in Japan