Panasonic and Mitsubishi Gas Chemical Develop Eco-friendly Urea Resin with Methanol Produced from CO2

—Reduces CO2 emissions by 20-30% compared to conventional methods—

April 10, 2025

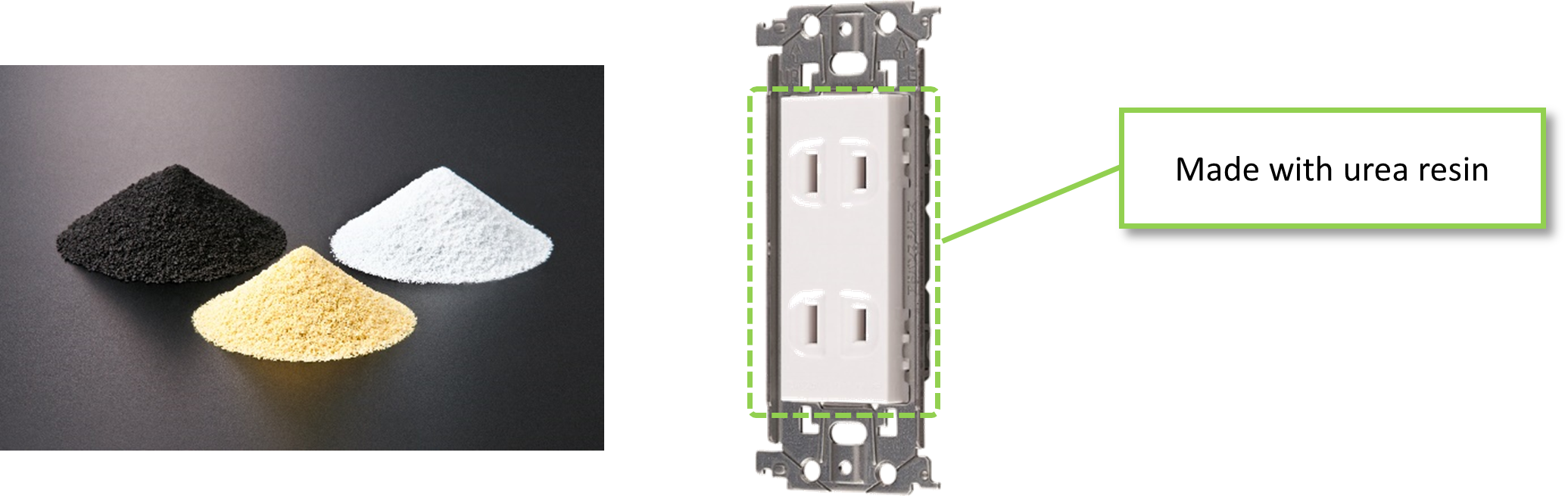

Mitsubishi Gas Chemical Company, Inc. (MGC; Head Office: Chiyoda-ku, Tokyo; President: Yoshinori Isahaya) today announced that in collaboration with Panasonic Electric Works Company (Panasonic) it has used methanol produced from CO2 to develop an environmentally friendly urea resin, a process shown to reduce CO2 emissions by 20-30% compared to conventional methods.1 The new resin is targeted at wiring devices such as electrical outlets.

Photos of press conference (held on April 10th, 2025)

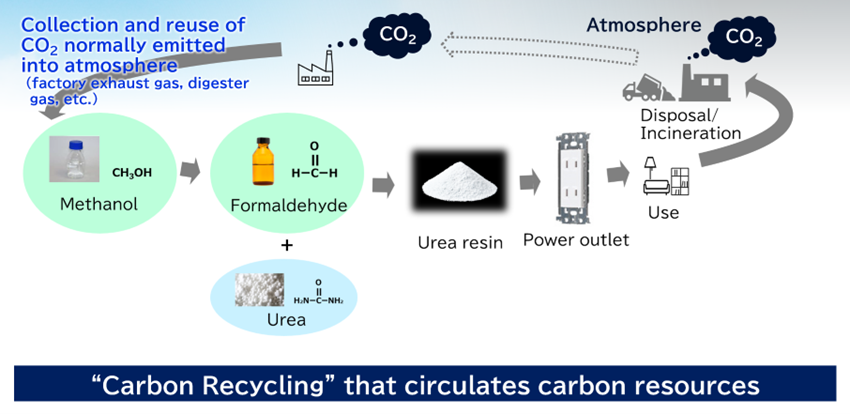

MGC Woodchem Corporation, a MGC subsidiary, will use methanol that MGC produces from CO2 to manufacture formaldehyde that it will supply to Panasonic, which will produce environmentally friendly urea resin for use in wiring devices that the company aims to begin selling in 2025 or later.

The new eco-friendly urea resin has the same molding and physical properties as conventional urea resin, so it can be used with existing manufacturing equipment to produce and connect wiring devices of the same quality as conventionally made products. However, the new resin reduces CO2 emissions by about 20-30% compared to conventional urea resin, and reduces the carbon embodied in buildings that use these end products.2

Urea resin is a thermosetting resin derived from the reaction of urea and formaldehyde. With its excellent tracking and arc resistance, it is used in electrical sockets and many other electrical components that must ensure electrical safety. Although it cannot be melted after hardening, even with heat, which prevents it from being recycled, MGC and Panasonic’s new eco-friendly manufacturing process achieves carbon recycling3 by using methanol, the raw material for urea resin, produced from CO2.

MGC has the technology and business know-how to produce methanol from CO2, waste and biomass, and then use the resulting green methanol as fuel and in everyday products. To this end, MGC has established and promotes Carbopath™ as a platform for developing and supplying methanol that is contributing to a decarbonized, recycling-oriented world. Going forward, MGC will continue to accelerate cross-sector partnerships and collaborations with related industries and local governments for the production and use of green methanol.

More information about Carbopath™ can be found at: https://www.carbopath.mgc.co.jp/en/

1 Independent estimate based on the raw materials used to produce urea resin, but not including CO2 emissions of producing, processing and transporting the resin.

2 For CO2 emissions from the construction, maintenance and demolition of buildings, separate from emissions associated with building use (operational carbon).

3 CO2 is a carbon resource that is captured and recycled as a variety of carbon compounds (source: Agency for Natural Resources and Energy, Ministry of Economy, Trade and Industry website).

[Details of the collaboration]

Main Roles:

- Mitsubishi Gas Chemical: Production of methanol from CO2

- MGC Woodchem: Production of formaldehyde from methanol

- Panasonic: Production of urea resin and wiring devices from formaldehyde

[Urea resin and Electrical outlet]

[About Panasonic Electric Works Company]

The Electric Works Company is in the business of providing innovative, people-centered electrical equipment for all of society's “life spaces,” from homes, offices and hotels to commercial and sports facilities. We are in the business of bringing customers a better today and a better tomorrow through electrical equipment.

END

Inquiries

Public Relations Department

Administrative & Personnel Division

MITSUBISHI GAS CHEMICAL COMPANY, INC.

TEL: +81-3-3283-5040