Lighter and longer-life products

Polycarbonate Resin

Production capacity

No.3 Worldwide

Shattering the idea that beauty is fragile

The strength of metal and the transparency of glass

Polycarbonate, also known as PC resin, is a type of engineering plastic, which is a generic term for plastics that are specially designed for enhanced strength, temperature resistance, and other mechanical properties. Polycarbonate resin is primarily used for industrial applications, such for machine parts and electronic components, where its light weight and superior shock absorption qualities provide a distinct advantage over heavier, more rigid materials. Polycarbonate resin’s high transparency coupled with its sturdiness and non-shatter properties also make it a viable and safe replacement for glass.

Mitsubishi Gas Chemical’s polycarbonate sheet and film products offer the optimal mixes and variations of these properties. Our PC resin provides added value to products in numerous industries with particularly high usage in automobile parts, smartphones, and game consoles.

Mitsubishi Gas Chemical’s polycarbonate sheet and film products offer the optimal mixes and variations of these properties. Our PC resin provides added value to products in numerous industries with particularly high usage in automobile parts, smartphones, and game consoles.

01Transparent but strong! 200 times stronger than glass.

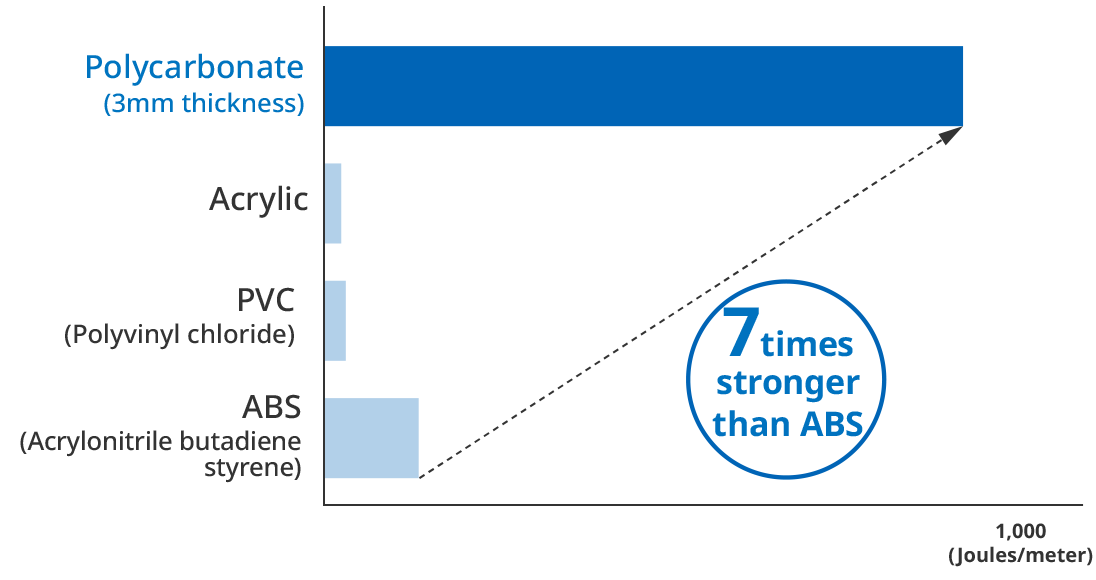

Polycarbonate’s most outstanding property is its sturdiness. At over 200 times stronger than glass, it is one of the most durable transparent plastics available. Not only is it strong, it is also lighter than most other resins and substantially lighter in terms of weight per volume than glass, aluminum, and even steel. Polycarbonate resin defies the common images that transparent materials are necessarily fragile and strong materials have to be heavy.

These properties enable polycarbonate resin products to be used in places where transparency is necessary and the risk of shattering is not acceptable. In Japan, the police replaced metal riot shields with polycarbonate shields, which offer equivalent protection but are lighter and provide better visibility. The same features favor polycarbonate resin instead of glass in the windows on airplanes and Japan’s high-speed Shinkansen trains. The triple combination of strength, lightness, and transparency also makes it ideal for an endless range of applications, including for everyday items like snow shovels and the covers of LED streetlights. Manufacturers are increasingly using polycarbonate resin parts to enhance the value added of their products, and consumers are benefitting from durable, convenient, and safer products.

Polycarbonate resin also has high thermal stability and fire resistance properties enabling it to be used in environments where other plastics commonly break down structurally, such as in places with wide fluctuations in hot and cold temperatures. Polycarbonate resin vastly expands the potential applications of engineered plastic, promising new benefits for manufacturers.

Izod impact strength

02Bright, beautiful and with excellent formability

Polycarbonate resin is strong, has high plasticity, and retains its clear transparency even through processing. Because it is a plastic, it is also very moldable, easily forming into virtually any shape and design. Early in its development, polycarbonate resin was only feasible for certain types of processing. MGC developed polycarbonate sheet production technology in 1967 and achieved mass production technology for polycarbonate sheet in 1971. Making these advances available to other manufacturers launched the rapid proliferation of various polycarbonate products and applications.

Polycarbonate resin has become the favored material for applications where requiring a polished look, such as smartphones, automobile interiors, and electronic goods. It’s also a standard material for innumerable everyday items, such as stationery products, kitchenware, and many sundry goods. Its strength and formability allow it to be used in processes that plastic previously couldn’t be used, and this has vastly expanded the design possibilities. Polycarbonate resin’s combination of strength and clear transparency has made it a fundamental engineering plastic.

Mitsubishi Engineering-Plastics Corporation, a joint venture company created by Mitsubishi Gas Chemical and Mitsubishi Chemical, received the Good Design Award in 2017 for its high design quality polycarbonate (HDQP) resin.

03Broader production potential heralds a new era for engineering plastic

Polycarbonate resin’s excellent material properties and lighter weight compared to other materials can help extend the lifespan of products incorporating PC resin parts. This leads to better performance and less waste, reducing the environmental impact. Manufacturers also recognize how this improves the added value of their products and are rapidly replacing parts made from other materials with polycarbonate resin parts. PC resin parts are becoming the norm in many industries, with examples ranging from parts and casings for medical equipment and industrial products, headlight covers on automobiles, and windows in airplanes. The uses for polycarbonate resin are growing exponentially with new applications being developed almost daily.

Bonus Feature!Polycarbonate resin eyewear for elite athletes

The clear transparency and virtually unbreakable properties of polarized sheet made from polycarbonate resin are fueling a revolution in glasses and sunglasses. Elite athletes choose eyewear made with lupilon for their ability to withstand harsh conditions while providing clear visibility and eye safety. Iupilon eyewear helps athletes perform at their best.