For nano-level cleansing

Super-Pure Hydrogen Peroxide

MGC global market share

No.1

Not a speck remains

Ultrapure solutions for semiconductor production

The hydrogen peroxide sold in stores that everyone knows is used in household cleansers, disinfectants, and bleach products. Our hydrogen peroxide is made of ultrapure hydrogen peroxide to meet the extremely high specifications of semiconductor manufacturing processes. MGC’s super-pure hydrogen peroxide is the “ultimate cleansing solution.” We engineered it specifically for the manufacturing processes of highly integrated devices. Factories worldwide that are making the high-performance technologies on which our society relies use MGC hydrogen peroxide.

01Supporting semiconductor industry cleansing and etching

The laptop computers, tablets, car navigation systems, and smartphones that we are so familiar with are constantly being designed to be more compact and offer better performance, which requires parts and materials that also provide higher performance.

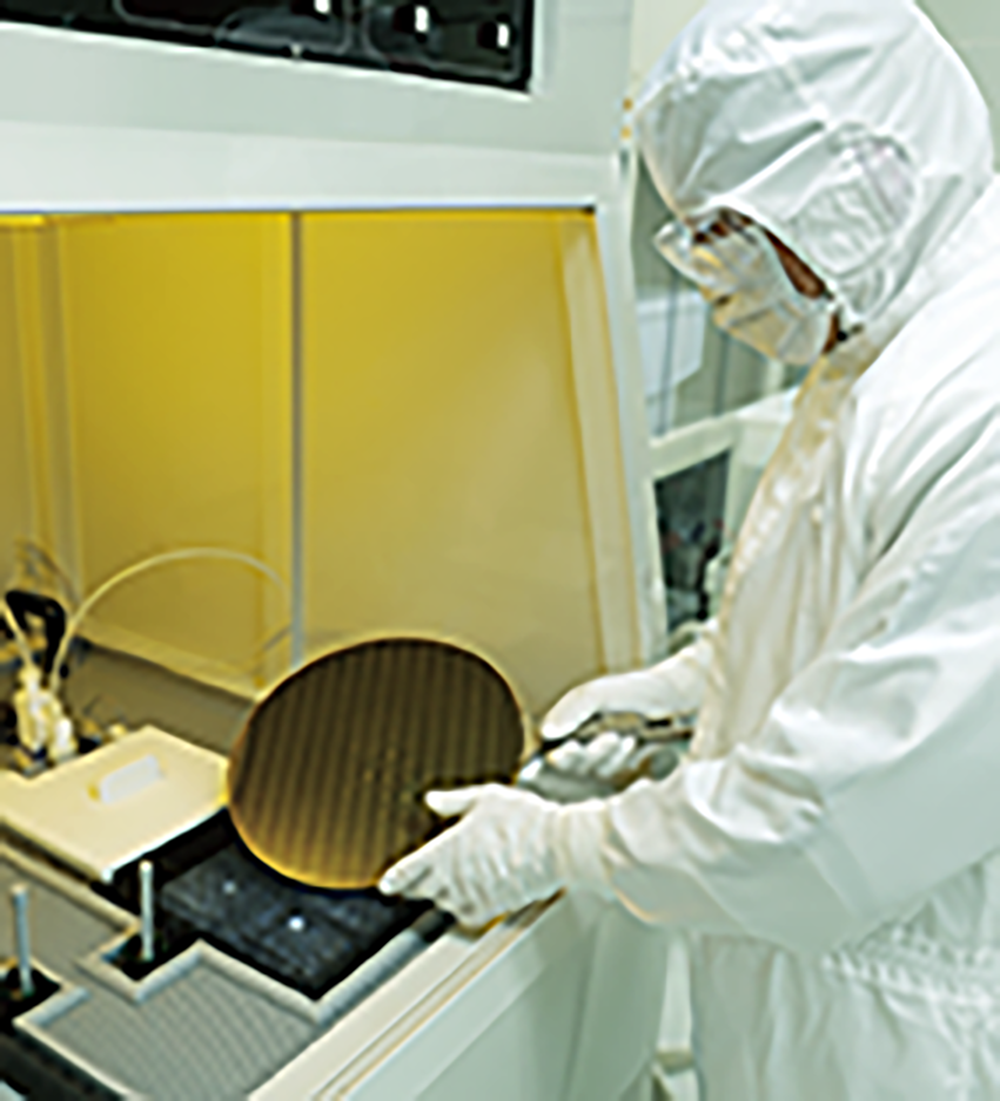

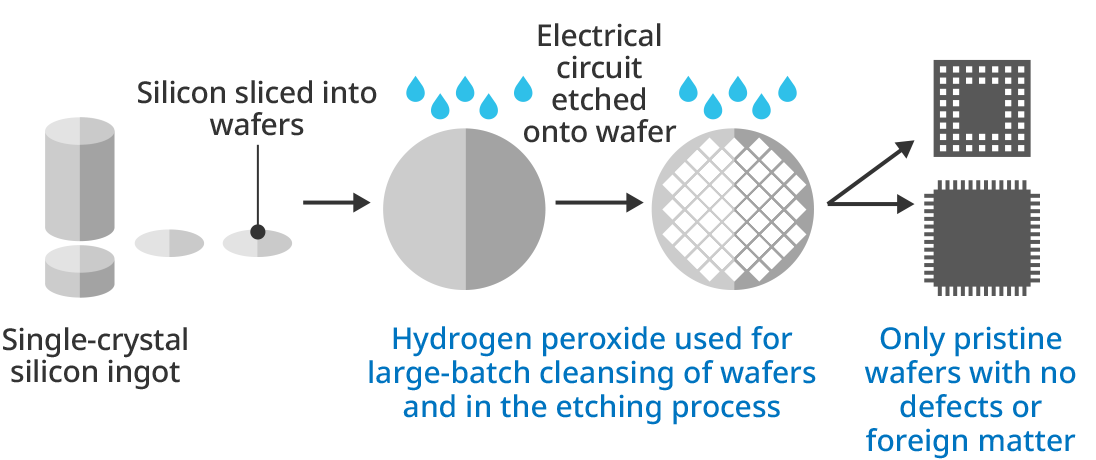

Semiconductors are essential to making all of these devices perform better. A speck of dust or foreign matter on a computer chip can not only reduce the performance but can cause a malfunction or crash. Super-pure hydrogen peroxide provides the high degree of purification necessary for high-performance electronics. Our research in enhancing hydrogen peroxide, also known as oxydol (which has hydrogen peroxide as the main ingredient), led to MGC becoming the first Japanese company to successfully produce super-pure hydrogen peroxide solution to wash foreign matter and dust away from semiconductors. Our solution is used in etching and other manufacturing processes to ensure the products are washed clean of all foreign matter. Etching is the removal of layers from the surface of a semiconductor chip during manufacturing using a special solution or gas. Our hydrogen peroxide is an unseen but essential element used by chipmakers worldwide.

02Super-pure hydrogen peroxide—the ultimate cleanser

Super-pure hydrogen peroxide is used to cleanse semiconductors substrates. Why is a special solution needed? The answer is the small size of the wafers on which semiconductor chips are mounted. Making electronic devices and semiconductors more compact means these wafers also must be made smaller, and the circuitry on these wafers now has a delicate structure on the nano scale (1 nanometer is one-millionth of a millimeter).

The ultrafine debris created during the semiconductor fabrication and processing must be removed from the chips. Regular water cannot be used because it is unable to completely wash away the nanomicron-sized debris without degrading the wafer’s nanoscale structure. The super-pure hydrogen peroxide solution we formulated is a superb chip cleanser that is not only used by chipmakers worldwide but also by makers of liquid-crystal components and printed wiring boards. When including other uses, such as an etchant solution, MGC is the world’s leading provider of ultrapure hydrogen peroxide.

Semiconductor production flow

03Purity is the starting point for new technologies and products

The smooth operating performance of the leading-edge technologies that are revolutionizing our information society is possible because their materials and components are first bathed in super-pure hydrogen peroxide solution. As the electronic devices we use become smaller and more powerful, our solution will continue to be a key part of their manufacturing processes.