Joint Study Proposal Selected by New Energy and Industrial Technology Development Organization for the Development of Technology for Producing Raw Materials for Plastics Using CO2 and/or Other Sources

February 18, 2022

Tosoh Corporation

Mitsubishi Gas Chemical Company, Inc.

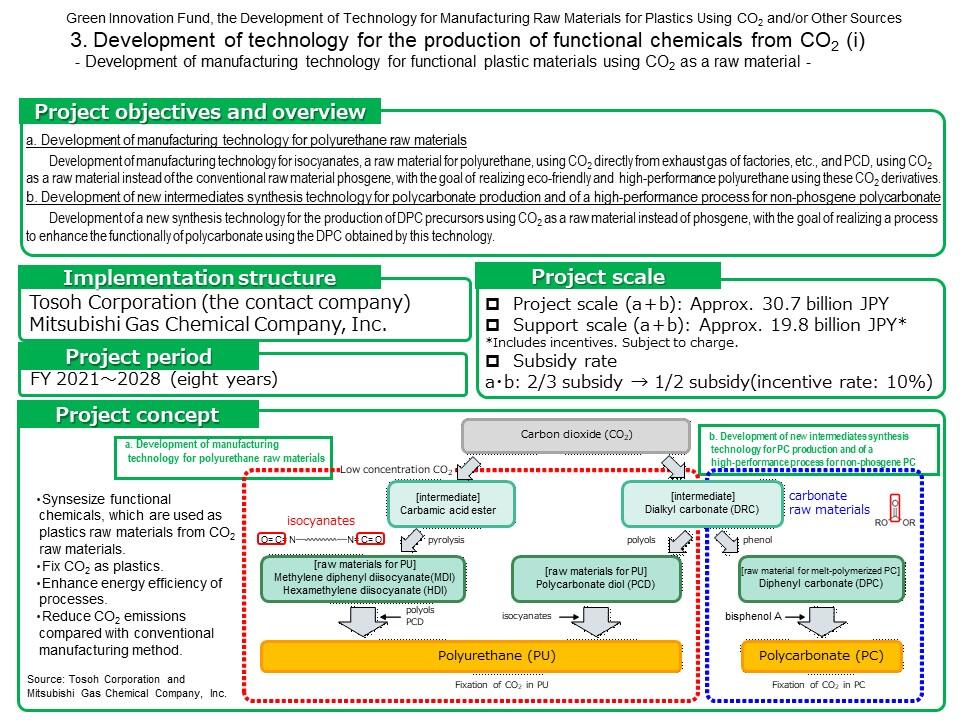

Tosoh Corporation (Tosoh; the contact company) and Mitsubishi Gas Chemical Company, Inc. (MGC) managed the parties involved in a joint proposal selected by Japan’s New Energy and Industrial Technology Development Organization (NEDO). That proposal—the “Development of Technology to Manufacture Functional Plastic Materials from CO2”—responded to NEDO’s call for proposals for its “Development of Technology for Producing Raw Materials for Plastics Using CO2 and/or Other Sources.” Implementation is funded by the Green Innovation Fund, R&D classification item No.3 of the “Development of Technology for Producing Functional Chemicals from CO2.”

Our proposal collaborators include the Interdisciplinary Research Center for Catalytic Chemistry at the National Institute of Advanced Industrial Science and Technology (AIST); Professors Keiichi Tomishige and Yasuhiro Fukushima, of Tohoku University Graduate School of Engineering’s Departments of Applied Chemistry and of Chemical Engineering, respectively; Professor Masazumi Tamura, of Osaka City University’s Research Center for Artificial Photosynthesis; and Colcoat Co., Ltd.

These parties will now collaborate in aiming to reduce CO2 emissions during the manufacture of polycarbonate and polyurethane by eliminating from the process the need for the conventional raw material phosgene. They will, moreover, strive to achieve technology to convert CO2 into a raw material for plastics production by 2030. Their hope is to achieve the same plastics manufacturing cost as currently while improving the functionality of the plastics produced. To those ends, they will pilot the production of several hundred to several thousand tons of plastics per year.

The Japanese government’s goal of carbon neutrality by 2050 looms large in this project’s efforts to develop technology to capture CO2 for use as a raw material for plastics. Using CO2 in place of phosgene as a raw material to produce dialkyl carbonate and isocyanates, the raw materials for polycarbonate and polyurethane, will reduce CO2 emissions well below those generated with phosgene. This, in turn, will reduce overall greenhouse gas (GHG) emissions in plastics production from raw material to finished product. Proposed process modifications, moreover, will improve the functionality of polycarbonate and polyurethane.

This project will also accelerate the development of manufacturing technology for functional chemicals using CO2 as a raw material. To ensure the widespread future use of that technology, the project collaborators will conduct a life cycle assessment of the chemicals it yields.

Project partner Tosoh believes that its efforts to reduce GHG emissions in light of climate change will lead to its medium- to long-term business growth. The company, therefore, continues to contribute to the realization of a sustainable society, promoting the development of technologies to raise energy use efficiencies; to reduce GHG emissions; and to separate, recover, and convert CO2 for use as a raw material.

MGC will use CO2 as a raw material to develop an intermediate for the polycarbonate manufacturing process that emits fewer GHGs than conventional processes. By applying this technology to the development of high-performance polycarbonate, MGC aims to develop and demonstrate functional chemical manufacturing technology for polycarbonate on a commercial scale toward achieving carbon neutrality by 2050.

Fig. Project overview

This News release document (in English) is translated by Tosoh.

END

Inquiries

Public Relations Department

Administrative & Personnel Division

MITSUBISHI GAS CHECMICAL COMPANY, INC.

TEL: +81-3-3283-5040