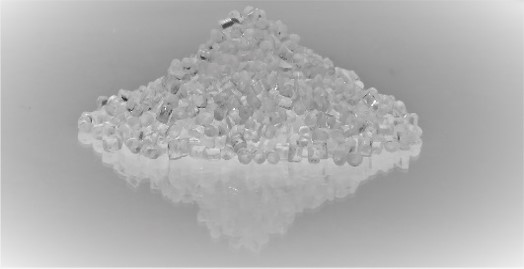

LEXTER™, Biobased Polyamide Resins

LEXTER™ is a family of crystalline polyamide resins produced by olycondensation of xylylenediamine with sebacic acid.

Features

- Higher mechanical strength and greater elastic modulus (compared to other polyamide resins)

- Lower water absorption and moisture permeability (compared to other polyamide resins)

- Made from biomass-derived raw materials

Application

- Film and filament

- Molding parts

Physical Properties

LEXTER™ is available in a wide range of grades with different melting points.

Table: LEXTER™ Injection Molding Properties*

| Property | Measuring Method (reference value) |

Unit | LEXTER™ #8000 |

LEXTER™ #8500 |

LEXTER™ #8900 |

PA6 | PA66 |

|---|---|---|---|---|---|---|---|

| Melting point (Tm) | DSC | ℃ | 190 | 215 | 290 | 220 | 260 |

| Glass transition point (Tg) | DSC | ℃ | 60 | 63 | 75 | 48 | 50 |

| Density | (ISO 1183) | g/cm³ | 1.12 | 1.12 | 1.12 | 1.12 | 1.14 |

| Tensile strength | (ISO 527-1) |

MPa | 90 | 90 | 90 | 62 | 77 |

| Tensile modulus | (ISO 527-1) |

GPa | 3.1 | 3.1 | 3.1 | 2.6 | 3.3 |

| Water absorption (Water immersion equilibrium/20℃) |

MGC method | % | 2.5 | 2.5 | 2.5 | 11.5 | 9.9 |

* The above data are measured value and are not guaranteed values.

Health and Safety Properties

- Compliant with the specifications and standards in Ministry of Health, Labour and Welfare Notification No. 370.

- Existing chemical No.: 7-1973 (polyxylylene sebasamide)

- Cas. Reg. No. 25102-41-4 (Decanedioic acid polymer with 1,3-benzenedimethanamine) Cas. Reg. No. 26046-30-0 (Decanedioic acid polymer with 1,3-benzenedimethanamine and 1,4-benzenedimethanamine)

Cas.Reg.No.28879-24-5Cas. Reg. No. 28879-24-5 (Decanedioic acid polymer with 1,4-benzenedimethanamine)

Inquiries Concerning Products

Green Energy & Chemicals Business Sector

High-performance Products Division

HP Material Department

TEL:+81-3-3283-4800 / FAX:+81-3-3214-0938